TM 5-3805-292-23

0007

HYDRAULIC SYSTEM

0007

Loader Main Relief Adjustment

0007

1. If hydraulic oil is not at operating temperature:

a. Start engine. Run at full throttle and hold implement joystick in rollback position for 30 seconds

(TM 5-3805-292-10).

b. Return implement joystick to neutral for 15 seconds.

c.

Repeat steps a and b until temperature of oil is at least 125F (52C) or side of reservoir is very warm.

d. Shut down engine (TM 5-3805-292-10).

WARN I N G

DO NOT disconnect or remove any hydraulicsystem line or fitting unless engine is shut

down and hydraulic system pressure has been relieved. Tighten all connections before

applying pressure. Escaping hydraulic fluid under pressure can penetrate the skin,

causing injury or death to personnel.

Use a piece of cardboard, newspaper, or wood to check for pressurized leaks to prevent

fluid from penetrating the skin. Failure to follow this warning may cause injury or death to

personnel.

N OT E

Make sure both flowmeter hoses are connected to machine.

Make sure load valve is fully open on flowmeter.

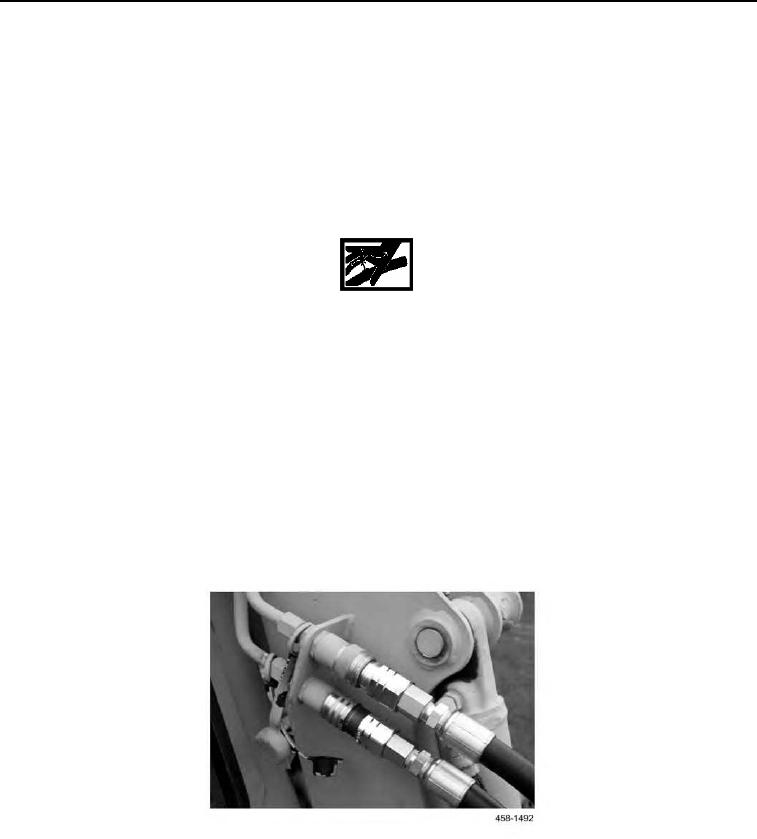

2. Connect flowmeter inlet to the upper auxiliary hydraulic coupler on left loader arm and set flowmeter on LO

flow setting.

Figure 28. Flowmeter Connections.

0007

3. Release park brake.

0007-27