TM 5-3805-298-23-2

0155

Table 1. Kickout System Will Not Operate or Operates Improperly Continued.

0155

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

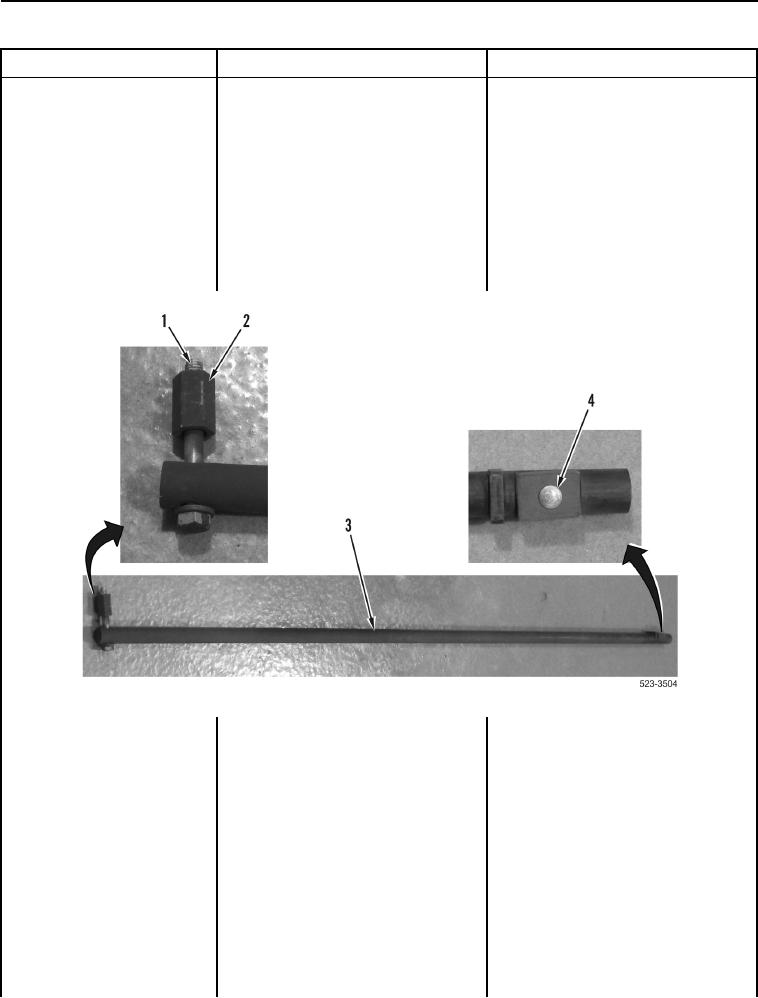

6. Inspect shaft (Figure 5, Item 3),

Kickout System Will Not

Shaft and Components OK Proceed

magnet (Figure 5, Item 4), bolt

Operate or Operates

to step 7.

(Figure 5, Item 1), and jam nut

Improperly - Continued

Shaft or Components Corroded or

(Figure 5, Item 2) for corrosion and

Damaged Replace shaft.

damage.

Proceed to Test Step 60.

7. Verify magnetic force of magnet by

Magnet Operates Proceed to Test

placing magnet (Figure 5, Item 4)

Step 7.

near machine surface.

Magnet Does Not Operate Replace

shaft.

Proceed to Test Step 60.

Figure 5. Shaft, Magnet, and Mounting Hardware.

0155

Test Step 7. Inspect Green (Power)

LED on Kickout Position Sensors.

1. Turn battery disconnect switch and

ignition switch to ON position

(TM 5-3805-298-10).

2. Set implement disable switch to

unlock position

(TM 5-3805-298-10).

3. Set kickout switch to ON position

(TM 5-3805-298-10).