TM 5-3805-255-14

0090

INSTALLATION CONTINUED

NOTE

Seal must be installed on side of sleeve with chamfer on outside diameter to avoid

damage to seal lip.

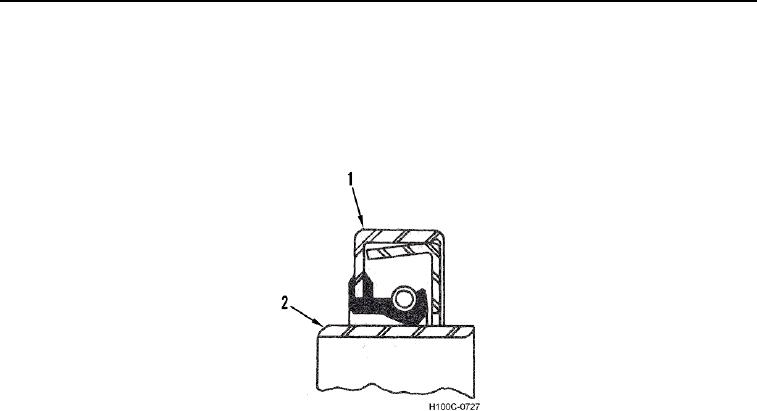

3. Install seal (Figure 13, Item 1) on sleeve (Figure 13, Item 2).

Figure 13. Assembling Seal to Sleeve.

0090

4. If loader is equipped with a crankshaft rear oil seal retainer, assemble retainer to flywheel housing making sure

it is centered to crankshaft by using centering tool, 1 020 471 R1 (part of old installing tool PLT-513-7) and bolt

to flywheel housing. Tighten Nylok capscrews to 20 lb-ft (27 Nm).

NOTE

Seal bore in retainer must be concentric with crankshaft within 0.010 in. (0.025 mm).

5. If removed, install flywheel housing.

CAUTION

Care should be taken not to get any of this RTV on seal lip or outside diameter of wear

sleeve. Failure to follow this Caution may result in damage to equipment.

NOTE

At no time should seal be removed from sleeve during assembly.

6. Coat inside diameter of wear sleeve and outside diameter of rear main oil seal with RTV.

7. Bolt crankshaft attaching adapter plate to crankshaft.

8. Place unitized seal assembly (Figure 13, Item 1) on adapter plate. Position radius on outside diameter of wear

sleeve (Figure 13, Item 2) toward rear.

0090-15