TM 5-3805-255-14

0090

INSTALLATION CONTINUED

Fitting Main Bearings

00090

1. Fit main bearings as follows:

NOTE

Do not turn crankshaft while following procedure is being performed.

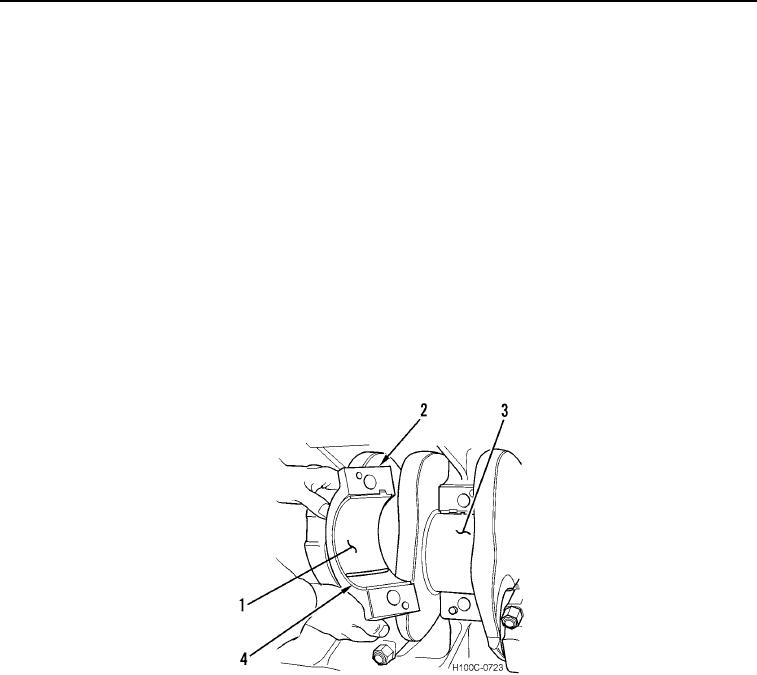

a. Remove center main bearing cap (Figure 11, Item 2) and lower main bearing (Figure 11, Item 1).

b. If virgin lead wire is to be used to check bearing clearance, wipe clean and oil crankshaft journal (Figure

11, Item 3). If Plastigage is to be used, wipe bearing surface and exposed half of crankshaft journal free of

oil as plastic material is soluble in oil.

c.

Place a suitable length of 0.010 in. (0.25 mm) virgin lead wire or a piece of Plastigage (Figure 11, Item 4)

across bearing surface (Figure 11, Item 1) and install bearing and cap. Tighten capscrews to 235 lb-ft

(320 Nm). Remove bearing cap. If virgin lead was used carefully remove wire, which will have been

crushed to amount of clearance present. Measure wire, using a micrometer. If Plastigage was used,

flattened plastic material will be found adhering to either bearing or crankshaft. DO NOT REMOVE

PLASTIGAGE. To determine bearing clearance, compare width of flattened plastic material at its widest

point with graduations on envelope.

Figure 11. Checking Main Bearing Running Clearance.

0090

0090-13