TM 5-3805-255-14

0090

INSTALLATION CONTINUED

d. If results obtained were within specified amount of 0.0026 to 0.0060 in. (0.066 to 0.152 mm), remove

Plastigage, coat bearing with clean engine oil (WP 0131) and install center main bearing cap. Torque two

capscrews to 235 lb-ft (320 Nm).

e. Continue checking other main bearings in same manner. Check rear main bearing next, followed by front

main bearing and then intermediate bearings.

f.

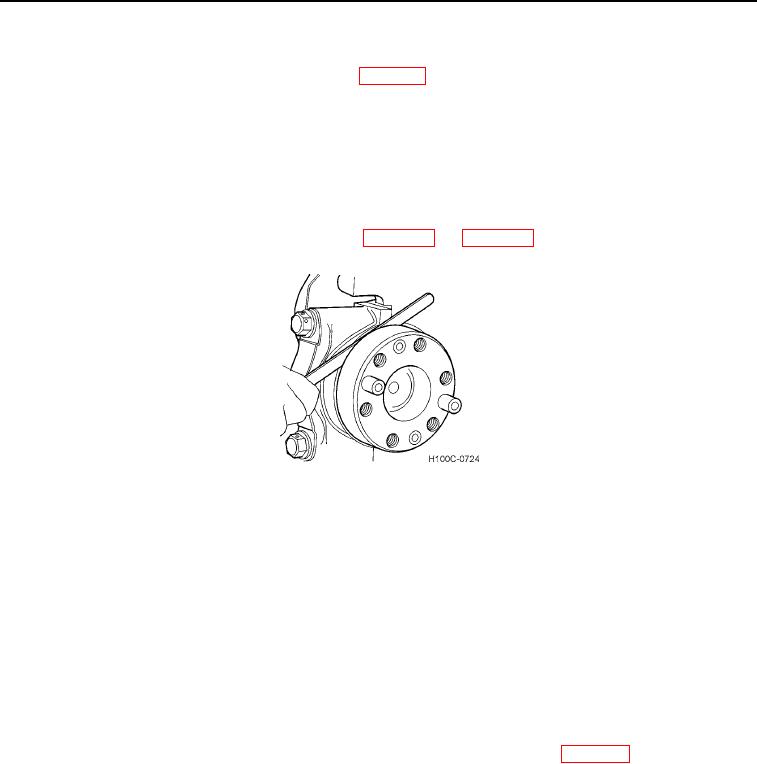

Check end-play present in crankshaft by inserting a feeler gauge equal to desired clearance of 0.005 to

0.011 in. (0.13 to 0.28 mm) (Figure 12). Should end-play clearance present be less that amount specified,

remove rear main bearing and grind off material equally from flange surface. Should clearance be more

than specified, replace rear main bearing with a new one.

g. Recheck connecting rod end play as outlined in WP 0093 and WP 0094.

Figure 12. Checking Crankshaft End Clearance.

0090

CAUTION

When rear main oil seal in flywheel housing is changed, oil seal bore should be checked

for a chamfer. If no chamfer is found use a file to break edge of bore in housing. Take care

not to damage bore while filing chamfer edge. This should be done to prevent possible

damage to rear main oil seal casing during installation.

2. Install a new crankshaft rear oil seal as follows:

a. Determine three evenly spaced tapped holes in crankshaft flange that will be used for driver tool bolts to

install seal and wear sleeve. One of tapped holes in flange is off-set 0.125 in. (3.175 mm) from equal

spacing and must not be used for installing seal and wear sleeve.

b. If oil seal and wear sleeve are not unitized (pre-assembled), assemble seal to sleeve before installing on

crankshaft as follows:

c.

Seal must be clean and lubricated. Coat single lip seal with clean engine oil (WP 0131). Double-lip seal

must have cavity between lips filled with Grade 251H-EP grease.

0090-14