TM 5-3805-258-24-2

ENGINE

PISTONS

DISASSEMBLY AND ASSEMBLY

INSTALL PISTONS

1214-12

Tools Needed

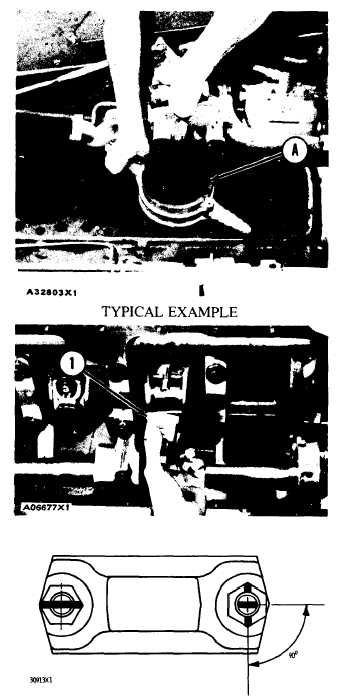

A

5P3525

Ring Compressor

1

1. Turn the crankshaft until the bearing journals for

the pistons to be installed are at bottom center.

2. Put clean engine oil on the crankshaft journals

and on the inside of the cylinder liners. Put clean

engine oil on the piston rings and connecting rod

bearings.

3. Move the rings on the piston until the ring open-

ings are approximate y 90° apart.

CAUTION

Never install the ring compressor on the piston

unless the cylinder liner is used as a guide.

Damage to the piston rings can be the result.

4.

5.

6.

Put ring compressor (A) in position on the cylin-

der liner. Put the connecting rod and piston in

position in the same cylinder liner from which it

was removed and into the ring compressor. Make

sure the “V” mark on the piston is in alignment

with the “V” mark on the cylinder block.

Push the piston into place as the connecting rod is

put into position on the crankshaft.

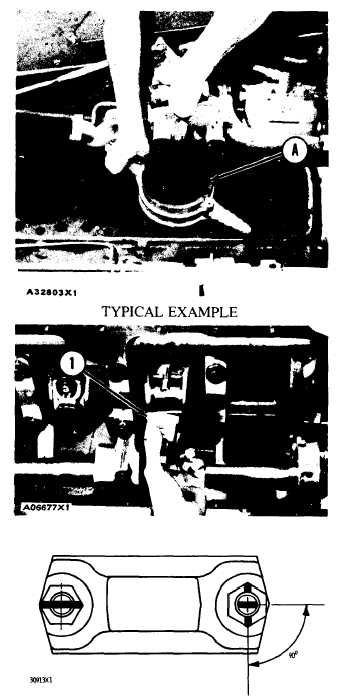

Put clean engine oil on bearings, bolt threads

and surfaces of the nuts that make contact with

the connecting rod caps. Put caps (1) in posi-

tion on the connecting rods and install the nuts.

Tighten the nuts to a torque of 40 ± 4 N·m (30

± 3 lb.ft.). Put a mark on each nut and the end

of each bolt. Tighten the nuts 90° more.

CAUTION

When connecting rod caps are installed, make

sure the number on the side of the cap is next to

and respective with the number on the side of

the connecting rod.

7. Follow the same above procedure for installation

of the remainder of the pistons.

end by:

a) install oil pan

b) install cylinder head

5-132