ENGINE

TM 5-3805-258-24-2

DISASSEMBLY AND ASSEMBLY

PISTONS

DISASSEMBLE PISTONS

1214-15

Tools Needed

A

B

Ring Expander

1

5F3639

Press Group

1

8F24

Hose Assembly

1

1P2375

Coupler Assembly

1

1P2376

Coupler Assembly

1

5F8719

Hand Pump (or electric)

1

6V2050

Tool Group

1

1.

2.

3.

4.

5.

6.

7.

8.

9.

start by:

a) remove pistons

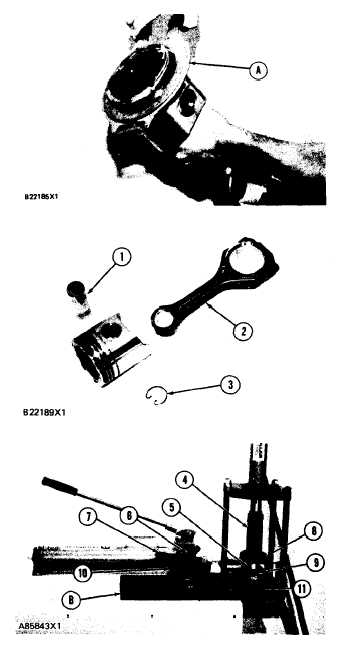

Remove the rings from the piston with tool (A).

Remove the bearings from the connecting rod

and connecting rod cap.

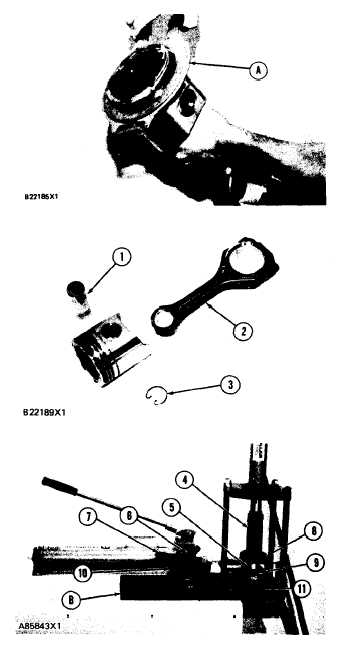

Remove retaining rings (3), pin (1) and con-

necting rod (2) from the piston.

See USE OF PISTON PIN BEARING RE-

MOVAL AND INSTALLATION TOOLS,

SPECIAL INSTRUCTIONS, Form No.

SMHS7295-02 for more information of re-

moval and installation of piston pin bearings.

Heat the connecting rod to a temperature of

176 to 260°C (350 to 500°F). Put 6V3029

Spacer (11) in the base plate. Put the connect-

ing rod on the base plate of tooling (B).

Put the connecting rod piston pin bearing end in

the center of the port assembly of tooling (B).

Install pin (6) in the center of the bore for the

connecting rod bearings.

Install 6V2049 Adapter (9). Put the hole in the

adapter in alignment with the hole in the base

plate of tooling (B).

Install clamp bar (10) and clamp pin (7).

Install new piston pin bearing (5) on adapter

(9).

NOTE: The old bearing is pushed out by tooling (B)

as the new bearing is installed.

10.

11.

12.

13.

14.

Put 5P8645 Adapter (8) in position as shown

with the taper side down. The piston pin bear-

ing joint must be in alignment with the hole in

adapter (9) and the base plate of tooling (B).

Put pusher (4) on adapter (8).

Use tooling (B) to push the new piston pin

bearing into the connecting rod until adapter

(8) of tooling (B) makes full contact with the

connecting rod surface.

Remove the connecting rod and the old piston

bearing from tooling (B).

Check the piston pin bearing bore diameter

after the bearing is installed. The correct di-

mension is 43.210 ± 0.008 mm (1.7012 ±

.0003 in.).

5-133