TM 5-3805-262-20

11-5. BUCKET CLAM CYLINDER ASSEMBLIES MAINTENANCE

a. I n s p e c t i o n .

This task covers inspection of bucket clam cylinder assemblies.

Perform this procedure anytime you suspect bucket clam cylinder assemblies problems.

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

NOTE

I f h y d r a u l i c o i l l e a k a g e i s s e e n , r e m o v e a n d r e p l a c e b u c k e t c l a m

cylinder assembly. Forward it to direct support maintenance for repair.

(1)

( 2 )

( 3)

(4)

(5)

(6)

(7)

(8)

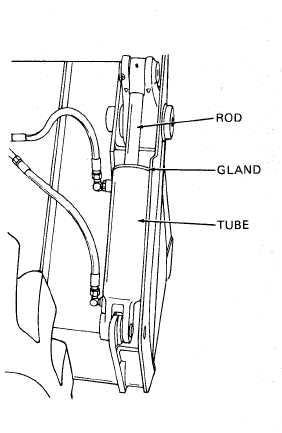

Check for indication of hydraulic oil

leakage between cylinder rod and gland.

If necessary, use clean cloth to remove

dirt and grease from area. Slight damp-

n e s s i s p e r m i s s i b l e.

Check for indication of hydraulic

oil leakage between gland and

tube. If necessary, use clean

cloth to remove dirt and grease

from area. Slight dampness is

p e r m i s s i b l e .

Start engine and operate at idle

speed.

Place CLAM control lever in OPEN

position until clam is one quarter

open.

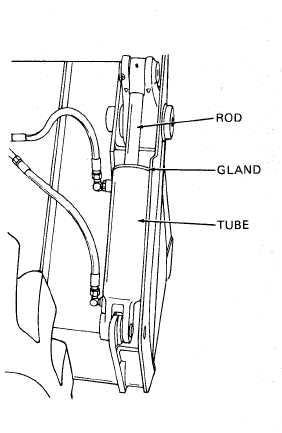

Check for indication of hydraulic

oil leakage between cylinder rod

and gland. Slight dampness is

p e r m i s s i b l e.

Check for indication of hydraulic oil

leakage between gland and tube. Slight

dampness is permissible.

Close clam and turn off engine.

Repeat steps (1) through (7) above to inspect remaining bucket clam cyl-

inder assembly.

1 1 - 71