TM 5-3805-262-34

CLEANING, INSPECTION, AND REPAIR (SHEET 2 OF 4)

(2) Check forward clutch carrier (17) and

associated parts (13 thru 16) by

rotating pinion gears (15). Pinion

gears must rotate smoothly. Inspect

teeth of pinion gears for cracks,

breaks, or wear. Check gear splines for

cracks, breaks, or wear. If any pinion

gears are damaged or don’t rotate

smoothly, replace as follows:

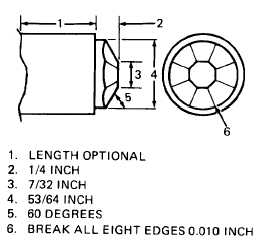

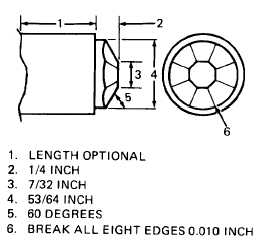

(a) Make special tool shown. This tool is

used to stake pinion spindles (13)

after new pinion spindles are in-

stalled. If you cannot make this

special tool, replace forward clutch

carrier (17) and associated parts (13

thru 16) as a complete assembly.

Do not drill into forward clutch carrier (17). The diameter of pinion

spindles (13) is slightly more than 3/4 inch. Center drill accurately to

prevent drilling into and damaging forward clutch carrier.

(b) Position forward clutch carrier in drill press with hub upward. Using

3/4 inch drill bit, drill into staked

NOTE

Do not discard pinion spindles (13). They

bly.

ends of four pinion spindles (13).

will be used to aid reassem-

(c) Put forward clutch carrier (17) in hydraulic press. Using 5/8 inch diam-

eter rod, press four pinion spindles (13) from forward clutch carrier.

(d) Remove eight thrust washers (14) and four pinion gears (15) from forward

clutch carrier (17).

(e) Remove 22 rollers (16) from each pinion gear (15).

Temperature of solid carbon dioxide (dry ice) is below -70 degrees F.

Wear insulated gloves to prevent severe skin injury. If skin is injured

by contact with dry ice, flush with large amounts of cold water to raise

temperature above freezing point and obtain medical aid immediately.

(f) Chill four new pinion spindles (13) in dry ice for one hour. If dry ice

is not available, put pinion spindles in a freezer for two hours.

4-153