TM 5-3805-262-34

4-3. TRANSMISSION MAINTENANCE (CONT)

g. Output Shaft.

This task covers removal, cleaning, inspection, and installa-

tion of output shaft.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Safety glasses

Socket head screw key set

Torque wrench, 3/4 inch drive

Screwdriver

Socket wrench set, 3/8 inch drive

Socket wrench set, 3/4 inch drive

Mechanical puller kit

Hand hammer, 16 ounces

Automotive Mechanic-s Tool Kit

Hand hammer, 8 ounces

Hydraulic press

Sleeve, 2-1/8 inches inside diameter

Sleeve, 3-1/2 inches outside diameter

Awl

Rawhide hammer

Flange holding tool

Bearing removal collar

Capscrews, two, 7/16-20 NF by 1 inch long

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Non-hardening sealant (Appendix C, item 10)

Lubricating oil (Appendix C, item 15)

Transmission gasket kit (FSCM 73342 PN 6838897)

O-ring (FSCM 73342 PN 6880101)

REFERENCE: TM 5-3805-262-20

NOTE

PRELIMINARY PROCEDURE:

parking brake removed (refer to TM

5-3805-262-20), and high range clutch and transfer gear removed (page

4-174).

REMOVAL (SHEET 1 OF 3)

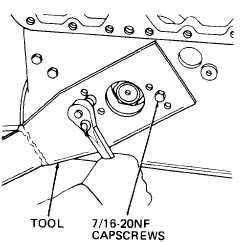

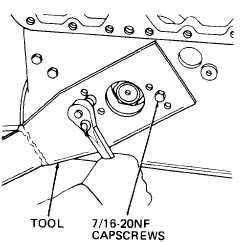

(1)

(2)

(3)

(4)

To prevent rotation of output flange (4),

install flange holding tool on output flange

and secure using two 7/16-20NF by 1 inch

capscrews as shown.

Loosen, remove, and discard lock nut (l).

Remove two 7/16-20NF by 1 inch capscrews and

flange holding tool from output flange (4).

Remove washer (2) and O-ring (3). If

necessary, use awl to remove O-ring. Discard

O-ring.

4-188