TM 5-3805-262-34

3-2. FUEL SYSTEM MAINTENANCE (CONT)

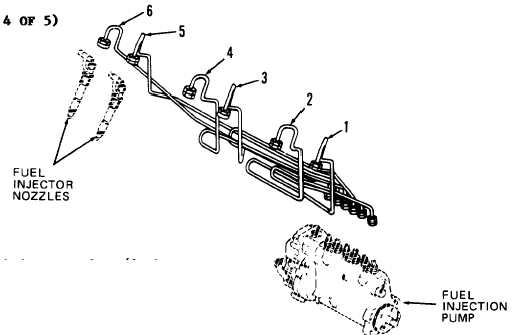

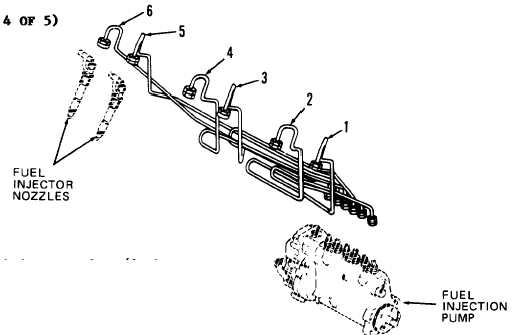

b. Fuel Injection Lines (Cont).

INSTALLATION (SHEET

LEGEND

1. Injector tube

2. Injector tube

3. Injector tube

4. Injector tube

5. Injector tube

6. Injector tube

(22) Position injector tubes (1 thru

6) as tagged during removal.

(23) Connect and hand tighten injector tubes

(1 thru 6) to fuel injector nozzles.

(24) Connect injector tubes (1 thru 6) to fuel injection pump. Tighten injec-

tor tube nuts finger tight, then tighten an additional 1/8 turn using

open end wrench.

NOTE

Perform following steps only if injector tubes (1 thru 6) were removed,

otherwise go to step (29) below.

(25)

(26)

(27)

(28)

Position six brackets (20) and plate (19) on injector tubes (1 thru 6).

Install and tighten three nuts (18) and capscrews (17).

Position two brackets (16) on injector tubes (1 and 2). Install and

tighten nut (15) and capscrew (14).

Position four brackets (13) and plate (12) on injector tubes (3 thru 6).

Install and tighten two nuts (11) and capscrews (10).

Install two brackets (9) on injector tubes (5 and 6). Install and tighten

nut (8) and capscrew (7).

Diesel fuel will spill from fittings in following step. Diesel fuel is

highly combustible. Do not smoke or allow open flames or sparks into the

area. Death or severe injury may result if personnel fail to observe

this precaution. If you are burned, obtain medical aid immediately.

(29) Watch tube fittings while assistant cranks engine. Tell assistant to stop

cranking engine when fuel comes out of fittings.

3-128