TM 5-3805-262-34

INSPECTION/REPAIR (SHEET 3 OF 4)

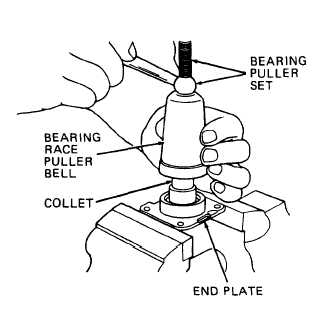

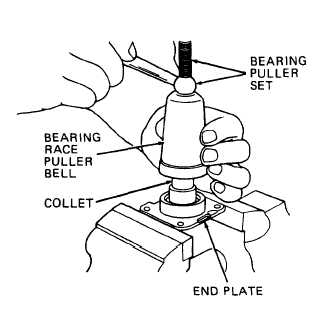

(f) Press bearing cups (83 and

84) from housing and end

plate using bearing puller

set.

(g) Remove oil seal (85) from

end plate and press in new

oil seal.

(h) Press new bearing cups (83 and

84) into housing and end

plate.

In following two steps, press

on inner diameter of bearing

cones to prevent damage to

bearings.

(i) Position stop ring (82) and shims (81) on drive end of camshaft (86).

Press on new bearing cone (80).

(j) Position stop ring (79) and shims (78) on governor end of camshaft (86).

Press on new bearing cone (77).

(k) Apply thin film of Molykote paste to surface of intermediate bearing

(4)

(5)

(6)

(76), then install intermediate bearing (76) on camshaft (86).

Inspect plungers (40) and barrels (58) for scratches, nicks, and vertical

grooves. Dip each plunger and mating barrel in clean calibrating fluid,

hold barrel vertical, and position approximately 3/4 of plunger length in

barrel. When released, plunger must slide down smoothly into barrel as

far as the stop on plunger vane. Replace plunger with barrel as an assem-

bly if any of the above conditions are seen.

Inspect delivery valves (57) for crushed or unevenly worn seats, grooved

bore, or thread damage. Inspect pistons (53) for cracks or vertical

grooves.

Insert each piston in its mating delivery valve and check free-

dom of movement. Replace delivery valve (57) and piston (53) if any of

the above conditions are seen.

Inspect control rack (48) for cracks, grooves, distortion, or chipped or

worn teeth. Repair slight grooving using abrasive cloths. Inspect thread-

ed ring (64), retainer (65), and bushings (66) for cracks or burrs. In-

stall control rack (48) and slide back and forth. Control rack must not

wobble or jam. Replace threaded ring (64), retainer (65), and bushings

(66) if control rack wobbles or jams.

3-151