TM 5-3805-262-34

3-2. FUEL SYSTEM MAINTENANCE (CONT)

d. Fuel Infection Pump (Cont).

INSPECTION/REPAIR (SHEET 4 OF 4)

(7)

Inspect springs (42) for damaged protective

and 55) for corrosion, cracks, or permanent

(8)

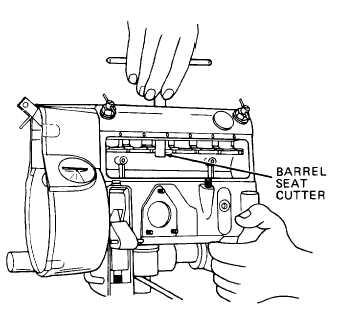

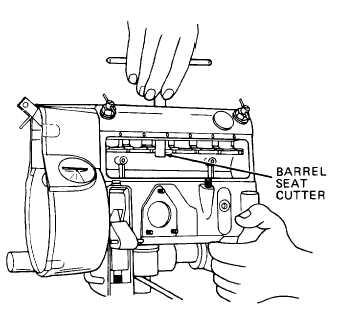

Inspect housing (68) for

cracks, distortion, or thread

damage. If necessary, smooth

barrel seats using light cuts

with barrel seat cutter. Re-

place housing (68) with plugs

(28 and 62), threaded ring

(64), retainer (65), and bush-

ings (66) as an assembly if any

of the above defects are seen.

(9)

Inspect drive gear (12) for

cracks, elongated holes, and

chipped, worn, or damaged

teeth. Drive gear to idler gear

backlash recorded during remov-

al must be less than 0.012

inch.

coating. Inspect springs (42

set.

(10) Inspect control sleeves (43) for cracks, worn slot, and worn or damaged

adjusting holes. Inspect gear segments (46) for cracks, thread damage, or

chipped or worn teeth.

(11) Inspect all other parts for cracks, distortion, excessive wear, or thread

damage.

REASSEMBLY (SHEET 1 OF 12)

(1)

Mount housing (68) in swiveling vise using mounting flange and U-bracket

and install governor housing (page 3-185).

NOTE

Perform steps (2) through (5) below only if inspection required removal

of parts.

(2)

If removed, apply thread sealant to threads of baffle screws (67). In-

stall six baffle screws (67) and tighten to 15 to 17 lb-ft.

3-152