TM 5-3805-262-34

INSPECTION/REPAIR (SHEET 1 OF 4)

(1) Inspect four studs (20 and 21) located on timing gear cover for cracks

and damaged or stripped threads. Repair thread damage by chasing with

3/8-16 die. If threads cannot be cleaned up, remove stud using pliers and

install new stud in timing gear cover.

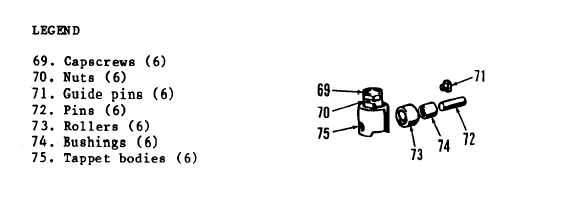

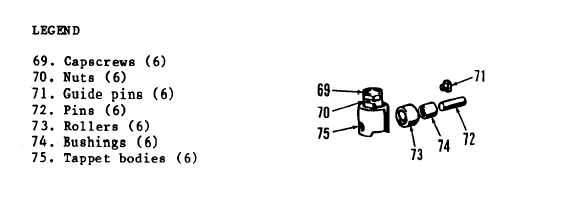

(2) Inspect roller tappets (69 through 75) by rotating roller (73) and check-

ing that it turns smoothly without wobble. Check for flat spots, pitting,

scratches, or cracks. If any of the above conditions are seen, repair

roller tappet:

(a)

(b)

(c)

(d)

(e)

(f)

(g)

Measure and record height of capscrew (69) above tappet body (75). Then

loosen nut (70), remove capscrew (69) with nut (70), and remove guide

pin (71). Replace capscrew (69) if end worn or crushed or if thread dam-

age is seen.

Press pin (72) from bushing (74) and tappet body (75) using drive pin

punch. Replace pin (72) if bent or grooved.

Remove roller (73) with bushing (74) from tappet body (75).

Press bushing (74) from roller (73), and remove slight pressure marks

and vertical scoring from tappet body (75) using abrasive cloth. Replace

all other damaged or worn parts.

Press bushing (74) into roller (73), and position roller (73) in tappet

body (75).

Press pin (72) through tappet body (75) into bushing (74).

Install guide pin (71), nut (70), and capscrew (69). Turn capscrew (69)

to height above tappet body (75) recorded in step (a) above, then tight-

en nut (70) to secure.

3-149