TM 5-3805-262-34

INSPECTION, TESTING, AND REPAIR (SHEET 2 OF 7)

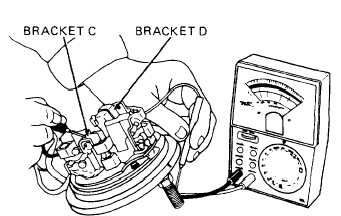

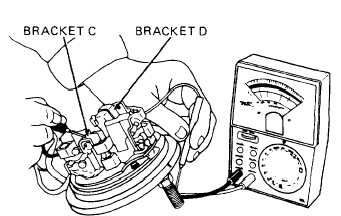

(3) Hold multimeter red lead on

plate assembly terminal stud,

black lead on bracket C. Note

multimeter indication. Move

black lead to bracket D and

note multimeter indication.

Multimeter should indicate

open circuit (multimeter

pointer should not move).

b. Inspect springs (18 and 66) for

cracks, broken or missing

coils, or permanent set.

c. Inspect drive assembly (44) for worn or damaged splines. Check teeth for

chips, cracks, and wear. Slide drive assembly onto armature (27) shaft and

check that it moves freely. Replace drive assembly (44) if any of the above

conditions are seen.

d. Inspect field coil (37) for damaged windings or distortion. Inspect field coil

leads for broken wire strands. Check terminal stud (39) for thread damage. If

thread damage is seen remove field coil from field frame, unsolder defective

terminal stud (39), and solder new terminal stud onto field coil. Replace

field coil if any of the above conditions are seen, or if field coil does not

pass the following tests:

(1)

(2)

(3)

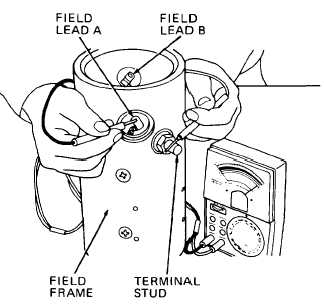

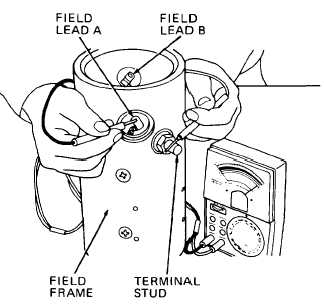

Hold multimeter red lead on

terminal stud, black lead on

field lead A. Note multimeter

indication. Move black lead to

field lead B and note multi-

meter indication. Multimeter

should indicate continuity

(multimeter pointer should

move) .

Hold multimeter red lead on

terminal stud, black lead on

field frame. Multimeter should

indicate open circuit (multi-

meter pointer should not

move).

Hold multimeter red lead on

field lead A, black lead on

field lead B. Multimeter

should indicate continuity

(multimeter pointer should

move).

3-235