TM 5-3805-262-34

2-4. ENGINE TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

10. LOW ENGINE OIL PRESSURE (Cont).

Step 9.

Step 10.

(Cont).

b. (Cont).

Install connecting rod cap and secure using two splined head

screws. Tighten to 95 to 105 lb-ft.

Repeat step 9 above for remaining five connecting rod caps. If

all clearances are 0.0011 to 0.0046 inch, go to step 10 below.

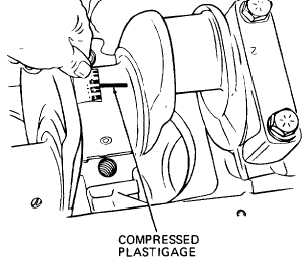

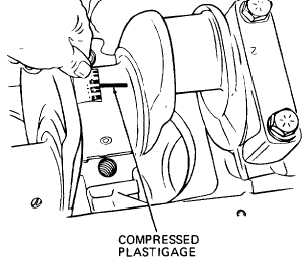

Remove two capscrews and washers securing main bearing cap.

Remove main bearing cap.

Put a piece of plastigage on crankshaft journal.

Put clean OE/HDO 30 lubricat-

ing oil on threads and under

heads of capscrews.

Install main bearing cap and

secure using two capscrews and

washers. Tighten to 195 to 215

lb-ft.

Remove two capscrews and wash-

ers securing main bearing cap.

Remove main bearing cap and

measure clearance indicated by

width of compressed plasti-

gage. Clearance must be 0.0016

to 0.005 inch.

2-40