TM 5-3805-262-34

2-5. FUEL SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. FUEL INJECTION PUMP NOT OPERATING PROPERLY (Cont).

Step 11.

Step 12.

(Cont).

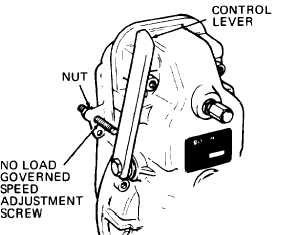

Back out swivel lever adjusting

screw three turns (12 clicks).

Position fuel control lever

towards no load governed speed

adjustment screw until governor

setting protractor scale indi-

cates 50 degrees. Adjust no

load governed speed adjustment

screw until it just touches

control lever. Release control

lever and push back until it is

stopped by no load governed

speed adjustment screw.

Protractor scale shall indicate

50 degrees. If necessary, read-

just no load governed speed

adjustment screw. Tighten nut

when adjustment is complete.

Turn on test bench and operate

fuel injection pump at 1140 to

1150 rpm.

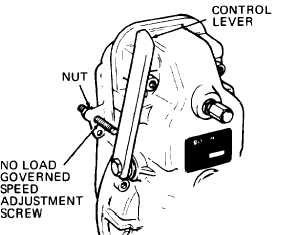

Push back fuel injection pump fuel control lever against no load

governed speed adjustment screw while watching rack travel dial

indicator. Dial indicator should indicate 0.441 inch.

Turn off test bench.

a. If rack travel dial indicator indicates 0.441 inch, go to step

14 below.

b. If rack travel dial indicator does not indicate 0.441 inch, ad-

just swivel lever adjusting screw. Do this by moving control

lever to stop position then adjusting screw. Turning adjusting

screw clockwise one click increases rack travel 0.0098 inch. Go

to step 12 below.

Turn on test bench and operate fuel injection pump at 1140 to 1150

rpm.

Push back fuel control lever against no load governed speed adjust-

ment screw and check that rack travel dial indicator indicates ex-

actly 0.441 inch.

2-62