TM 5-3805-290-23-1

HYDRAULIC SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0017 00

RELIEF VALVE (LINE) TEST AND ADJUSTMENT

0017 00

N OT E

Use Table 1 to determine line relief specification for cylinder that is being serviced.

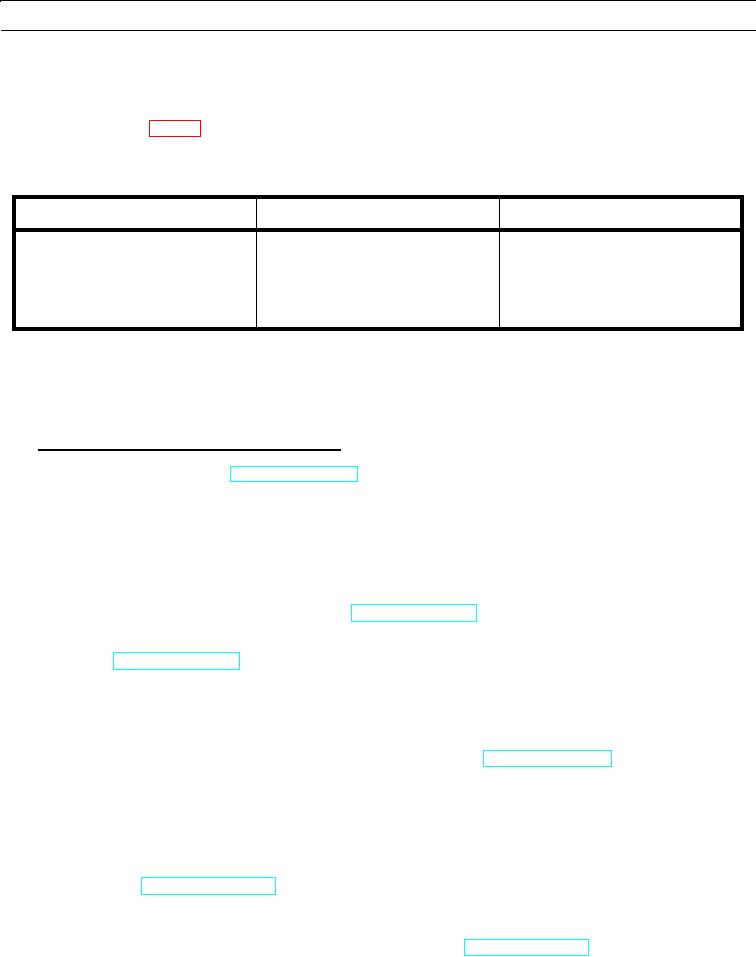

Table 1. Line Relief Specifications for Cylinders.

CYLINDER

HEAD END

ROD END

Tilt

1,775 29 psi

4,000 50 psi

(12,300 200 kPa)

(27,550 350 kPa)

Auxiliary for third function hydraulic

3,250 50 psi

3,250 50 psi

arrangement

(22,400 350 kPa)

(22,400 350 kPa)

N OT E

Before testing line relief valve, perform step 3 of Piston Pump Pressure Test and Adjustment in this work

package.

1.

Line Relief Valve for Head End of Tilt Cylinder.

a.

Connect steering frame lock (TM 5-3805-290-10).

b.

Remove right chassis cover (WP 0107 00) for access to combination valve (1).

c.

Connect pressure gage to hose.

d.

Connect other end of hose assembly to test port (2) of line relief valve (3) for head end of tilt cylinder.

e.

Start engine. Run engine at high idle. Operate control levers and move all cylinders to increase temperature of

hydraulic oil to normal operating temperature (TM 5-3805-290-10).

f.

Raise arm to half of full height and dump bucket until cylinder rods are fully extended. Continue to raise lift arm

slowly (TM 5-3805-290-10). Observe pressure at port (2) for head end of tilt cylinder. As lift arms raise, linkage

pushes rod into cylinders.

g.

Observe gage at test port (2) for relief valve setting and record pressure. Setting for relief valve should be 1,775

29 psi (12,238 200 kPa).

h.

If line relief valve (3) is not set to correct specifications, stop engine (TM 5-3805-290-10). Adjust line relief valve

by performing steps i and j.

i.

Loosen locknut (4). Turn adjusting screw (5) clockwise to increase relief valve setting. Turn adjusting screw coun-

terclockwise to decrease relief valve setting.

j.

After adjusting screw (5) is adjusted, tighten locknut (4) to 3 1 lb-ft (4 1 Nm).

k.

Start engine (TM 5-3805-290-10).

l.

Observe pressure gage and record pressure for head end of tilt cylinder.

m.

When pressure settings for line relief valve are correct, stop engine (TM 5-3805-290-10) and remove test equip-

ment.