TM 5-3805-291-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

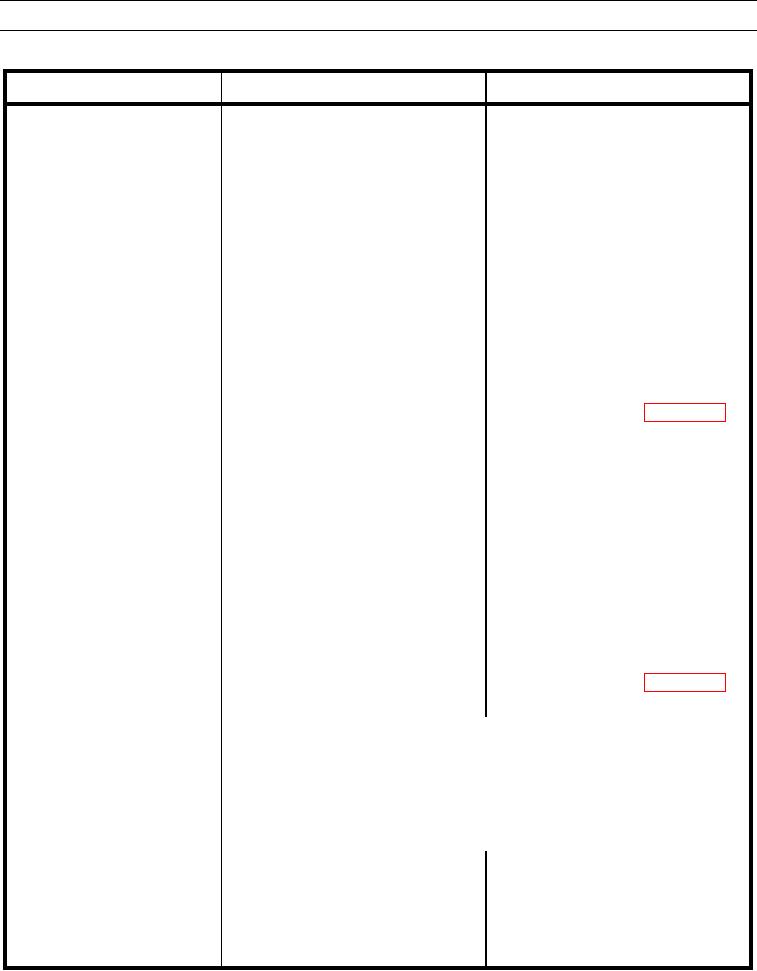

Table 8. AC System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Check low and high pressure gage

1. If low pressure gage reading is above

6.

Compressor Will Not

during operation of AC.

normal and high pressure gage reading

Engage. Air Flow to

is below normal, go to Test 2.

Operator's Compartment is

2. If readings are not as specified, exit this

Warm.

test.

2. Check AC compressor.

1. If problem is loose wire on switch or a

(a) Check wire connectors on

loose wire on magnetic clutch, make

thermostatic switch and on

repairs that are needed or replace

compressor clutch.

compressor (WP 0221 00).

(b) Check for insulation that is

2. If wires to clutch were damaged,

broken.

damaged wires can cause switch to

(c) Check for clutch coil resistance of

remain open. Make needed repairs to

17.6+/- 0.6 Ohms with a

damaged wires.

3. After system is charged, operate for a

(d) Check for proper electrical ground

minimum of 10 minutes (TM 5-3805-

291-10) and perform Performance

at magnetic clutch.

Checks for AC System (WP 0018 00) to

(e) Touch two wires on switch

together. Check for proper

verify correct operation of AC system.

operation of magnetic clutch.

4. If problem still exists, go to Test 3.

3. Refer to Electrical System

If problem still exists, go to Test 4.

Troubleshooting (Table 2 in this work

package) to check the AC control

system.

4. Check for lost charge of refrigerant in

1. If capillary tube has no charge or switch

capillary tube.

remains open, problem is in

thermostatic switch, replace

compressor (WP 0221 00).

2. After system is charged, operate for a

minimum of 10 minutes (TM 5-3805-

291-10) and perform Performance

Checks for AC System (WP 0018 00) to

verify correct operation of AC system.

N OT E

7.

Compressor Continues to

Cycle or Clutch Will Not

Cause of problem may be one of following conditions: low charge, over-

Disengage. Air Flow to

charge, or evaporator freeze-up.

Operator's Compartment is

Very Cold or Air Flow May

be Restricted Completely at

Times.

1. Check low and high pressure gage

1. If low pressure gage reading is below

during operation of AC.

normal and high pressure gage reading

is below normal, go to Test 2.

2. If readings are not as specified, exit this

test.