4

TM 5-3805-292-10

OPERATOR MAINTENANCE

-

PALLET FORK REPLACEMENT

0011

INSTALLATION, REMOVAL, OPERATION

INITIAL SETUP

References

Personnel Required

0

0

Two

0

0

0

INSTALLATION

0011

NOTE

Pallet fork installs on machine in the same way as hydraulic work tools, but without quick

disconnects.

1. Start engine. Refer to Starting Engine (WP 0005).

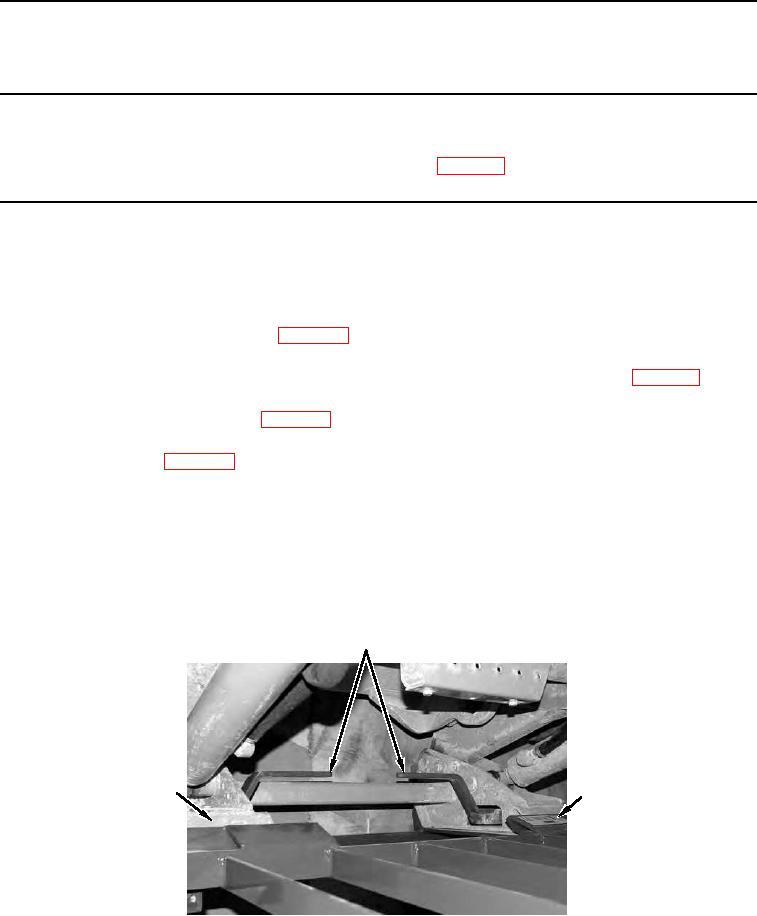

2. Tilt top of attachment coupler (Figure 1, Item 3) forward and slowly drive machine forward until top of attach-

ment coupler fits under frame lifting bracket (Figure 1, Item 2). Refer to Operating Machine (WP 0005).

3. Raise loader arms until top of attachment coupler (Figure 1, Item 3) engages frame lifting bracket (Figure 1,

Item 2). Refer to Operating Loader (WP 0005).

4. Tilt attachment coupler (Figure 1, Item 3) back so that attachment coupler and frame are in full contact. Refer

to Operating Loader (WP 0005).

WARNING

Do not touch control levers while assistant is locking manual locking levers. Failure to

follow this warning may result in injury or death to personnel.

5. With assistance, push manual locking levers (Figure 1, Item 1) fully down to lock pallet fork frame to attachment

coupler (Figure 1, Item 3).

1

3

2

458-0050

Figure 1. Coupling Pallet Fork.

0011