TM 5-3805-258-24-1

F U E L S Y S T E M

T E S T I N G

A N D

A D J U S T I N G

NOTE: When reference is made to crankshaft rota-

tion, the engine is seen from the flywheel end.

1. Put No. 1 piston at top center (TC) on the

compression stroke. Make reference to FIND-

ING TOP CENTER COMPRESSION POSI-

TION FOR NO. 1 PISTON.

2. Remove the timing bolt from the flywheel.

3. Remove No. 1 Fuel injection line and nozzle.

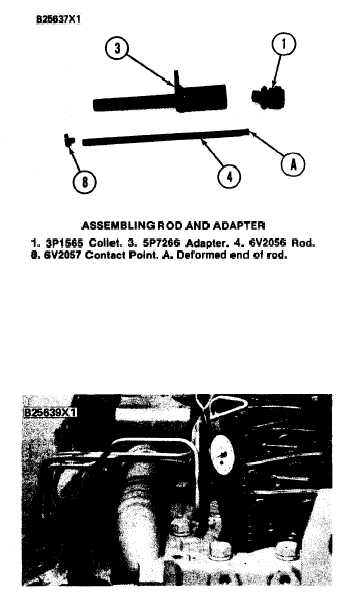

ASSEMBLING ROD AND ADAPTER

1. 3P1565 Collet. 3. 5P7266 Adapter. 4. 6V2056 Rod.

6. 6V2057 Contact Point. A. Deformed end of rod.

4. Put a small amount of clean oil on 6V2056

Rod (4) and put the rod in 5P7266 Adapter

(3). End (A) of the rod must be inside the

adapter. End (A) has been deformed and will

not let the rod fall through the adapter into

the cylinder. Install 6V2057 Contact Point (8)

on the end of rod (4).

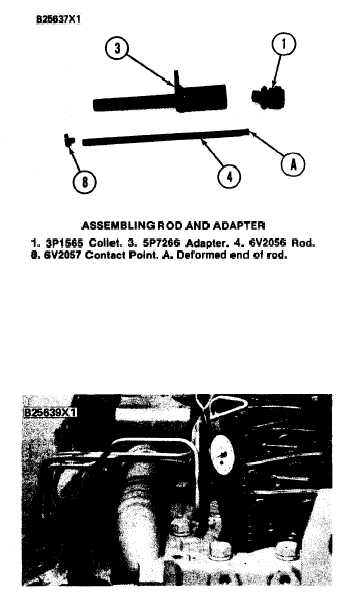

5.

D I A L

I N D I C A T O R

I N S T A L L ED

( T Y P I C A L

E X A M P L E )

Put adapter (3) in the same hole that No. 1

fuel nozzle was removed from. Fasten adapter

(3) to head with bolt and spacer from fuel

nozzle.

6.

7.

8.

Do

Install 3P1565 Collet (1) in the top of adap-

ter (3).

Install the 9S8883 Contact Point on 9S215

Dial Indicator (2) and put indicator (2) in

adapter (3) thru collet (1).

Position the dial indicator (up or down) so

small pointer is on “0” (zero) and tighten collet

(1).

CAUTION

not tighten collet too much or damage to

the dial indicator can result.

9. Loosen the screw that locks the dial face. Move

the dial face until the large pointer is on “0”

(zero) and tighten the lock screw.

10. Turn the crankshaft a minimum of 45 degrees

in a clockwise direction. Slowly turn the crank-

shaft in a counterclockwise direction until a

maximum reading is seen on the dial indicator.

Adjust the indicator up or down in the collet

until the revolution counter is at +.300 in.

(Black Numbers). Tighten the collet to hold

the indicator in this position. Loosen the bezel

lock and turn the bezel until the zero on the

face of the dial is in alignment with the hand.

Tighten the bezel lock.

11. Slowly turn the crankshaft in a counterclock-

wise direction until the dial indicator moves

beyond .020 in. Now turn the crankshaft in

the opposite direction until the dial indicator

is at .020 in.

12. Make a pointer from a piece of wire and install

under bolt of water pump. Make a temporary

mark on the vibration damper in relation to

the pointer.

CAUTION

Do not use a hammer and punch to mark a

vibration damper.

13.

14.

Turn the crankshaft in a clockwise direction

beyond the maximum indicator reading and

bevond .020 in. Now turn the crankshaft in a

counterclockwise direction until the dial in-

dicator is .020 in.

Make a second temporary mark on the vibra-

tion damper in relation tO the pointer. Now

make a mark on the vibration damper that is

one-half the distance between the two tem-

porary marks. This mark is the point of most

accuracy for top center No. 1 piston.

4-14.2