TM 5-3805-258-24-1

T E S T I N G

A N D

A D J U S T I N G

F U E L S Y S T E M

15. Turn the crankshaft in a clockwise direction

approximately 45 degrees and then turn the

crankshaft in a counterclockwise direction

to the top center mark that was made in Step

14. If needed, adjust the dial indicator as in

Step 10.

16. Turn the crankshaft in a clockwise direction

approximately 45 degrees.

17.

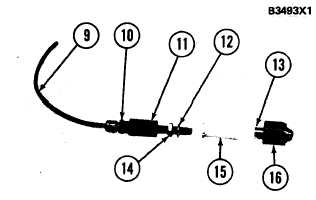

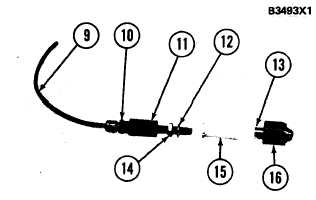

6 V 2 0 2 3 F L O W C H E C K I N G A D A P T E R G R O UP

9 . T u b e . 1 0 . C o n n e c t o r a s s e m b l y . 1 1 . F i t t i n g . 1 2 . S e a l-

ing washer. 13. Adapter. 14. Locknut. 15. Pin. 16. Nut.

18.

19.

Install 6V2023 Flow Checking Adapter Group

on No. 1 fuel injection pump. Use the proce-

dure that follows to install the group.

a.

b.

c.

d.

e.

f.

Turn fitting (11) out of adapter (13) until

5.0 mm (.20 in.) of pin (15) can be seen.

Put 6V2023 Flow Checking Adapter Group

on No. 1 fuel injection pump and tighten

nut (16) to 40 N·m (30 lb. ft.).

Turn fitting (11) into adapter (13) until

pin (15) just makes contact with the reverse

flow check valve in the fuel injection pump

bonnet. This is the point of first resistance.

Turn the fitting into the adapter an addi-

tional 1/4 turn.

Move sealing washer (12) against the adap-

ter. Tighten locknut (14) finger tight against

sealing washer (12).

Tighten tube (9) to connector assembly

(10) so that the end of tube (9) is in a posi-

tion above horizontal and higher than the

end on the connector assembly.

Disconnect the fuel line at the fuel filter. Use

an adapter to connect 5J4634 Hose Assembly

(19) to the fuel filter base.

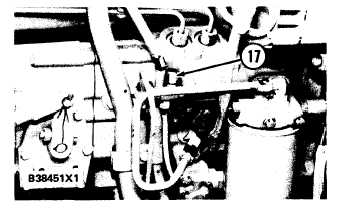

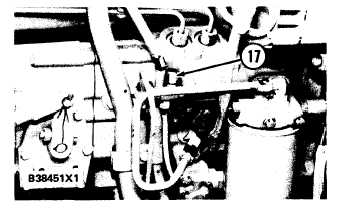

Disconnect the fuel return line from the con-

stant bleed valve. Put cap (17) on the constant

bleed valve.

F L O W C H E C K I N G A D A P T E R G R O U P I N S T A L L E D

( T Y P I C A L

E X A M P L E)

C O N S T A N T B L E E D V A L VE

( T Y P I C A L E X A M P L E)

17. Cap.

20. Put 1 gal. (4 liters) of clean fuel in the tank

assembly. Move the governor lever to full

FUEL-ON position. Put 105 kPa (15 psi) of

air pressure in the tank. Use the hand pump

or shop air.

CAUTION

If shop air is used, make an adjustment to the

regulator so the air pressure in the tank is a

maximum of 105 kPa (15 psi).

21.

22.

23.

Put pan (18) under the end of tube (9) for the

fuel that comes out of the tube.

Turn the crankshaft, slow, in a counterclock-

wise direction. Do this until the flow of fuel

from the end of tube assembly (9) is 6 to 12

drops per minute.

Stop rotation of the crankshaft when the flow

of fuel is 6 to 12 drops per minute. Take a

reading of the measurement on dial indicator

(3).

4-15