TM 5-3805-262-34

REASSEMBLY (SHEET 6 OF 6)

W A R N I N G

When using chain hoist to remove or install parts, be sure chain hoist

is securely fastened to the part and that all slack in chain is taken

up. Failure to do so could cause serious injury due to the part falling

on you.

If you are injured by falling equipment, obtain medical aid

immediately.

(39) Insert steel bar through differential case and gear assembly. Attach

chain hoist to steel bar and raise and position differential case and

gear assembly over differential carrier (27). SlOWlY lower assembly into

position in differential carrier. Disconnect chain hoist and remove steel

bar.

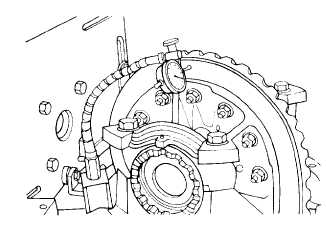

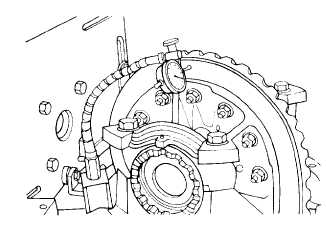

(40) Install one differential cap (4) with match marks alined.

(41) Install two washers (3) and capscrews (2).

Tighten to 290 to 350 lb-ft.

(42) Install adjusting ring (5).

(43) Position differential cap (4).

(44) Install two washers (3) and capscrews (2). Tighten to 290 to 350 lb-ft.

(45) Install adjusting ring (5).

Do not install two cotter pins

ADJUSTMENT OF DIFFERENTIAL BEARINGS

(1)

(2)

(3)

(4)

(5)

(6)

NOTE

(1) until adjustment has been completed.

Install dial indicator against

back side of differential case

and gear assembly ring gear.

Move differential case and gear

assembly back and forth to

check for end play.

If there is no end play, loosen

adjusting ring (5) at back side

of ring gear just enough to ob-

tain end play. Tighten other

adjusting ring (5) just enough

to obtain zero end play.

Rotate ring gear and check runout. If runout exceeds 0.008 inch, remove

differential case and gear assembly (steps (1) through (10), page 4-218)

and check that ring gear is installed correctly and that differential

case halves are properly assembled (page 4-238).

With runout less than 0.008 inch, tighten each adjusting ring (5) one

notch to put correct preload on differential case and gear assembly

bearings.

Adjust ring gear backlash.

4-231