TM 5-3805-262-34

3-2. FUEL SYSTEM MAINTENANCE (CONT)

d. Fuel Injection Pump (Cont) .

REASSEMBLY (SHEET 11 OF 12)

(e)

(f)

(g)

(h)

(i)

(j)

(k)

(l)

(21)

(22)

(23)

(24)

(25)

(26)

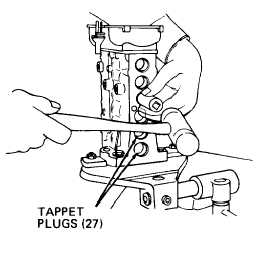

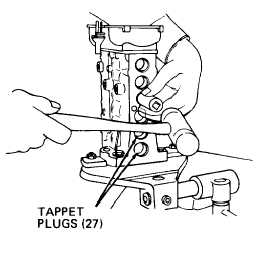

(27)

Press firmly and squarely inward on end play gage while swiveling it

and record dial indicator indication.

Remove dial indicator from end play gage.

Push a wood block into feed pump bore to prevent camshaft rotation, re-

move end play gage from camshaft, and remove wood block.

If end play measures 0.0008 to 0.0024 inch, go to step (21) below. If

end play does not measure 0.0008 to 0.0024 inch, go to step (i) below.

Remove end plate with camshaft, step (13) (page 3-142).

Remove end plate from camshaft (steps (20) through (22), page 3-145).

Press bearing cone from drive end of camshaft (step (d), page 3-150). If

end play is less than 0.0008 inch, remove shim(s) (81); if end play is

more than 0.0024 inch, add shim(s) (81). Press bearing cone on camshaft

drive end and install end plate (steps (5) through (7), page 3-153).

Install camshaft with end plate, steps (16) through (18) above.

Repeat steps (a) through (h) above to verify proper camshaft end play.

Aline camshaft intermediate bearing holes with housing holes.

Install and tighten two screws (38) with copper gaskets (39).

Install new O-ring (37) and coupling half (31).

Install lock washer (30) and nut (29). Tighten nut

lb-ft.

Using hammer and socket wrench, drive

six new tappet plugs (27) into housing.

Install and tighten elbow (26).

Turn camshaft until one lobe is TDC

(Top Dead Center) against roller

and remove tappet holder. Repeat

move remaining tappet holders.

tappet

to re-

(29) to 47 to 51

3-162