TM 5-3805-262-34

3-30. BUCKET LIFT ARMS AND PIVOT ASSEMBLIES MAINTENANCE (CONT)

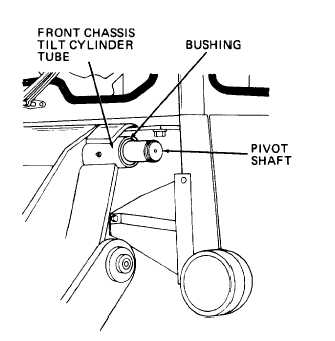

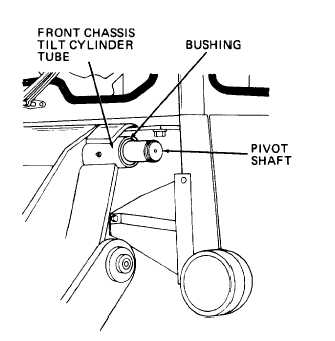

b. Tilt Cylinder Assemblies Pivot Shaft. This task covers removal, cleaning, in-

spection, and installation of tilt cylinder assemblies pivot shaft and bushings.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Safety glasses

Hand hammer, 3 pounds

Lubricating kit

Automotive Mechanic's Tool Kit

Machinist-s steel rule

Cold chisel

Slip joint pliers

Bore gage

Micrometer,

zero to 5 inches

Rod, 2-3/8 inches diameter by 50 inches long

Sleeve, 3 inches diameter

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Grease (Appendix C, item 7)

PERSONNEL REQUIRED: Two Construction Equipment Mechanics MOS 62B

REFERENCES: TM 5-3805-262-20

LO 5-3805-262-12

NOTE

PRELIMINARY PROCEDURE: Front flood lights and bucket

semblies removed (refer to TM 5-3805-262-20).

REMOVAL

(1)

Using hammer and 2-3/8 inches

diameter by 50 inches long rod,

drive tilt cylinder assemblies

pivot shaft from front chassis.

Have assistant support driving

end of rod until pivot shaft is

driven into chassis. When rod

is inside chassis, have assis-

tant move to opposite side to

support pivot shaft as it is

driven out.

(2)

If necessary to replace bush-

ings, use hammer and cold

chisel to split bushings from

front to back. Then use slip

joint pliers to remove bushings

from bores.

tilt cylinder as-

3-774