TM 5-3805-262-34

4-1. ENGINE MAINTENANCE (CONT)

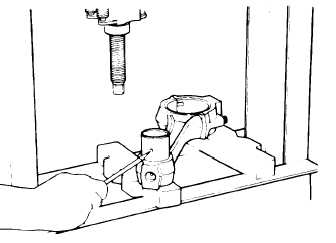

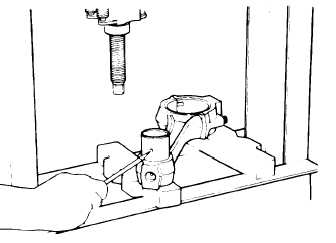

g. Pistons and confecting

Rods (CONT).

CLEANING

(1)

Break an old piston ring in half and use it to clean piston (3) ring

grooves.

(2)

Use a 0.156 inch diameter or smaller drill bit or fine wire to clean

piston (3) oil holes.

Dry cleaning solvent P-D-680 used to clean parts is toxic and flammable.

Wear protective goggles and gloves and use only in a well ventilated

area. Avoid contact with skin, eyes and clothes and don’t breathe

vapors . Do not use near open flame or excessive heat and don’t smoke

when using it. Failure to do so could cause serious injury. If you be-

come dizzy while using cleaning solvent, get fresh air and medical

attention immediately.

If contact with skin or clothes is made, flush

with

with

(3)

INSPECTION

(1)

(2)

(a)

(b)

(c)

large amounts of water. If contact with eyes is made, wash eyes

water and get medical aid immediately.

Clean all parts using cleaning solvent P-D-680. Dry using clean cloths.

AND REPAIR (SHEET 1 OF 2)

Measure and record piston pin (8) diameter using micrometer.

Measure inside diameter of bushing (9) using bore gage and micrometer

checking for wear. If inside diameter exceeds 1.6265 inches, press

bushing (9) from connecting rod

bushing:

Aline new bushing (9) oil

holes with connecting rod (2)

oil holes.

Using hydraulic press, press

bushing (9) into connecting

rod (2) until bushing is flush

with rod.

Using reamer, ream bushing (9)

0.0008 to 0.0014 inch larger

than piston pin (8) diameter

recorded above. If new piston

pin (8) is to be installed,

ream bushing to 1.6254 to

1.6258 inches.

new

(2) using hydraulic press. To install

4-46