TM 5-3805-262-34

4-1. ENGINE MAINTENANCE (CONT)

g.

Pistons and Connecting Rods (Cont) .

INSTALLATION (SHEET 1 OF 3)

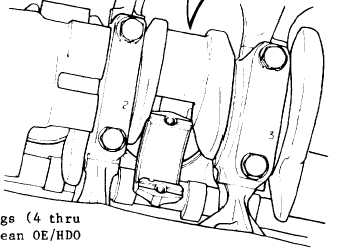

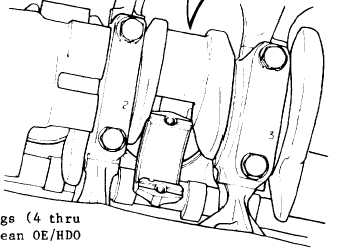

(1) Check connecting rod journals for wear

using micrometer. If diameters are

smaller than 2.748 inches use under-

size (0.002 inch) inserts. If connect-

ing rod journals are worn more than

0.002 inch, grind undersize to follow-

ing dimensions:

Outer Diameter

Grind

Undersize (inch)

to (inches)

0.010

2.738 to 2.739

0.020

2.728 to 2.729

0.030

2.718 to 2.719

(2)

Measure front and rear of each

crankshaft connecting rod jour-

nal using micrometer checking

taper. If taper exceeds 0.0005

inch, connecting rod journals

must be ground. Check connect-

ing rod journals 90 degrees

from first measurements for out

of roundness. If out of round-

ness exceeds 0.0005 inch, con-

necting rod journals must be

ground.

(3)

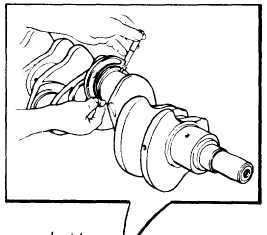

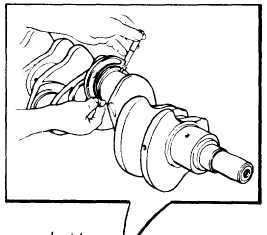

Lubricate piston (3), piston rin

6), and cylinder sleeve using cl

engine oil.

(4)

Install ring compressor on piston assembly.

NOTE

Be sure numbered side of connecting rod (2) matches cylinder number when

performing following step. Reinstall piston assembly in original

location.

Be sure stamped arrow on top of piston assembly points toward front of

engine.

(5)

Gently tap piston (3) assembly into cylinder sleeve using wooden dowel.

4-50