TM 5-3805-262-34

INSPECTION AND REPAIR (SHEET 2 OF 2)

(3)

(4)

(5)

(6)

Measure piston pin bore in piston (3) using bore gage and micrometer.

Subtract measurement recorded in step (1) above to obtain piston pin bore

clearance. If clearance exceeds 0.0021 inch, replace piston (3).

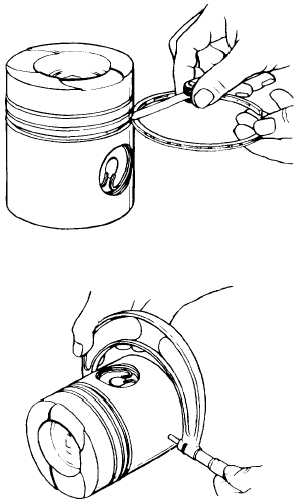

Use thickness gage to check

side clearance of oil ring (6).

If side clearance exceeds

0.0035 inch, replace piston

(3).

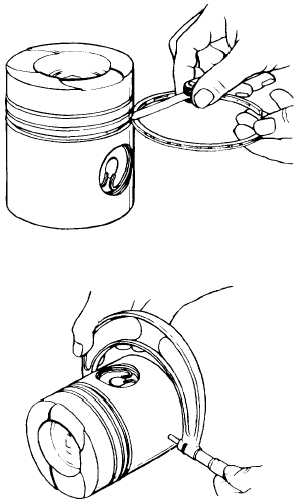

In same manner as above,

measure side clearance of

compression rings (4 and 5). If

side clearance exceeds 0.006

inch, replace piston (3).

Use micrometer to measure piston (3)

diameter at bottom of piston, perpen-

dicular to piston pin bore. Replace

piston if diameter is not between

4.6178 to 4.6198 inches.

NOTE

Replace an item if inspection

indicates need for replacement.

(7)

Inspect retaining rings (7) for

damage or loss of resiliency.

(8)

Inspect connecting rod (2) for

cracks, damage, wear, scoring, or

pitting.

(9)

Inspect inserts (10) for pitting,

flaking, cracking, or evidence of

overheating.

4-47