TM 5-3805-291-23-1

TROUBLESHOOTING WITH A DIAGNOSTIC CODE - CONTINUED

0009 00

Table 4. Implement Control - Continued.

(MID 082)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

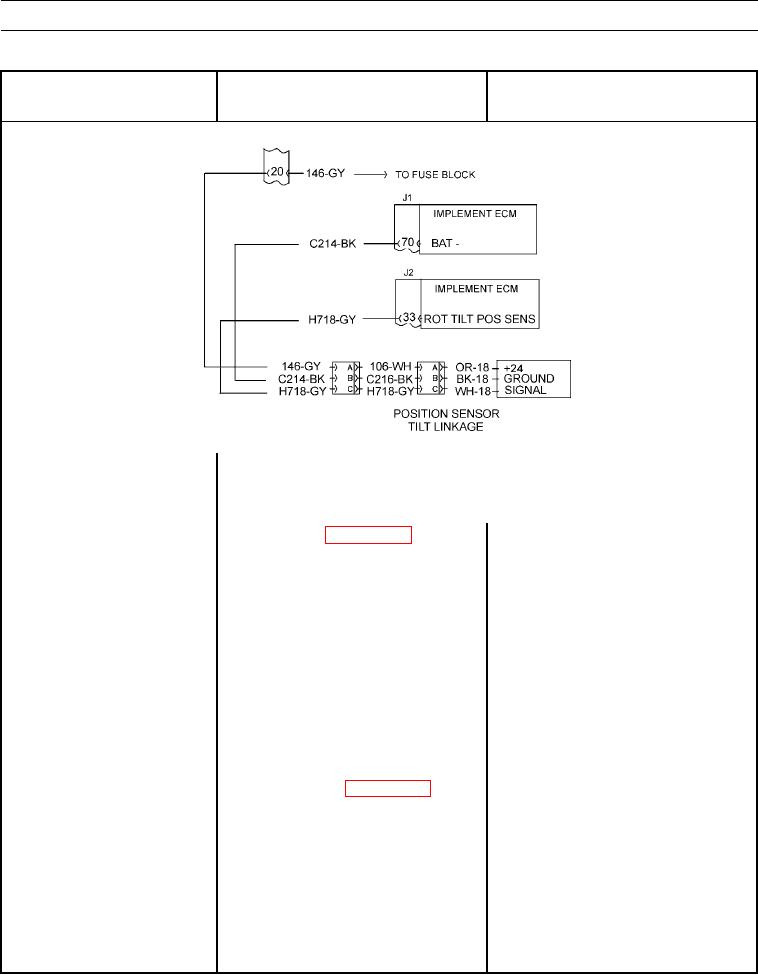

427-C1653

N OT E

0351 00

Ensure diagnostic code is active and diagnostic code indicator is

active.

1. Connect MSD (WP 0005 00) and check

adjustment of tilt linkage position sensor.

(a) Check mounting hardware for tilt

linkage position sensor. Fasteners

should be tight. If hardware shows

any sign of damage, hardware

should be replaced (WP 0089 00).

(b) Ensure diagnostic code is active.

(c) Observe ON/OFF status of

1. If diagnostic code is inactive, clear

diagnostic code indicator as tilt arm

diagnostic code.

is fully raised and lowered.

2. If diagnostic code indicator is active, go

to Test 2.

2. Check cycle time (WP 0017 00).

1. If cycle time is correct, go to Test 3.

2. If cycle time is not correct, ensure tilt

linkage position sensor is moving with

tilt linkage and go to Test 4.

3. Recalibrate position sensor (WP 0017

1. If diagnostic code is inactive, calibration

00) and check for an active diagnostic

has repaired machine.

code.

2. If diagnostic code is inactive, go to Test

4.