TM 5-3805-262-34

4-1. ENGINE MAINTENANCE (CONT)

j. Oil Pump.

This task covers disassembly, cleaning, inspection, and reassembly

of the oil pump.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Drill,

3/8 inch capacity

Drill bit, 1/8 inch diameter

Long nose pliers

Slip joint pliers

Screwdriver

Torque wrench, 1/2 inch drive

Safety glasses

Automotive Mechanic’s Tool Kit

Socket wrench set, 1/2 inch drive

Thickness gage

Machinist’s steel rule

Spring gage

Plastigage

Wood screw, number 12

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

DISASSEMBLY

Cleaning solvent P-D-680- (Appendix C, item 2)

Cotter pin (FSCM 10988 PN 132-32)

Plug (FSCM 10988 PN 41-1011)

NOTE

PRELIMINARY PROCEDURE: Engine oil pump removed (page 3-92).

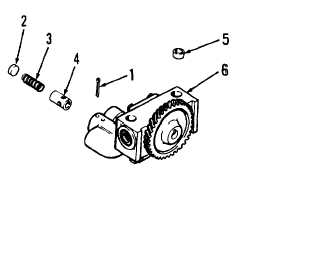

(SHEET 1 OF 2)

Spring (3) exerts outward pressure on plug

LEGEND

(2). If plug (2) is loose, plug and spring

1. Cotter pin

(3) may fly out of oil pump (6) bore when

2. Plug

you perform steps (1) through (3) below.

3. Spring

Use caution to avoid injury due to flying

4. Valve

parts. If you are injured, obtain medical

5. Sleeve

aid

(1)

( 2)

( 3)

4-74

immediately.

6. Oil pump

Remove cotter pin (1) from oil pump (6)

using long nose pliers. Discard cotter pin.

If plug (2) cannot be easily removed, drill

a hole through its center using 1/8 inch

diameter drill bit. Install a wood screw in

hole then use pliers to grip head of wood

screw and remove plug. Discard plug.

Remove spring (3) and valve (4).