TM 5-3805-262-34

INSPECTION (SHEET 2 OF 2)

NOTE

Replace an item if inspection indicates need for replacement.

(8)

Inspect oil pump (6) drive gear for

broken or missing teeth, pitting, or

distortion.

(9)

Inspect oil pump (6) body for cracks,

dents, distortion, or damage.

(10) Inspect valve (4) for cracks, dents, or damage.

REASSEMBLY

NOTE

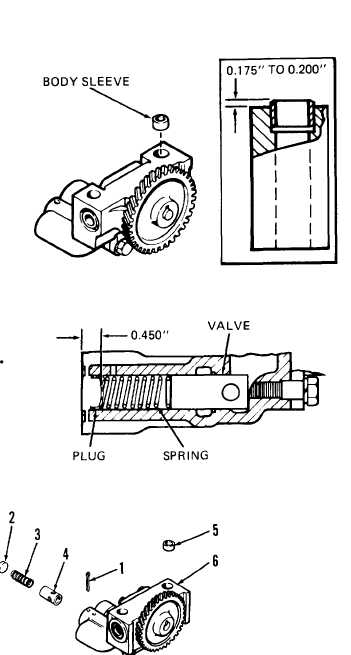

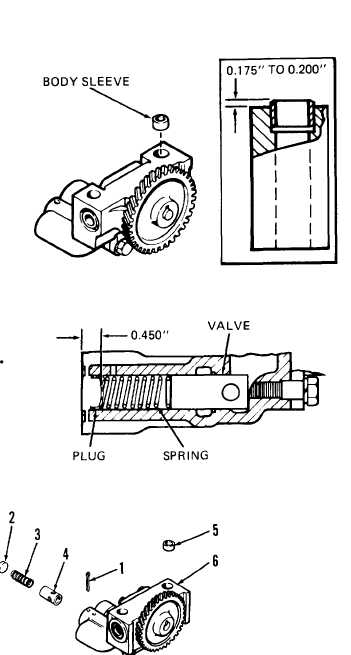

Perform step (1) below only if

sleeve (5) was removed.

(1)

(2)

(3)

(4)

( 5)

(6)

(7)

(8)

Install new sleeve (5) in oil

pump (6) body. Push sleeve in

until it protrudes 0.175 to

0.200 inch above oil pump

surface.

Install valve (4) in oil pump

(6) bore, oil holes inward.

Install spring (3).

Install new plug (2) to depth

of 0.450 inch.

Install and spread new cotter

pin (1) using long nose pliers.

Install oil pump (page 3-94).

Connect oil pump suction tube

to oil pump (page 3-94).

Install oil pan (page 3-90).

LEGEND

1. Cotter pin

2. Plug

3. Spring

4. Valve

50 Sleeve

6. Oil pump

4-77