TM 5-3805-291-23-1

TROUBLESHOOTING WITH A DIAGNOSTIC CODE - CONTINUED

0009 00

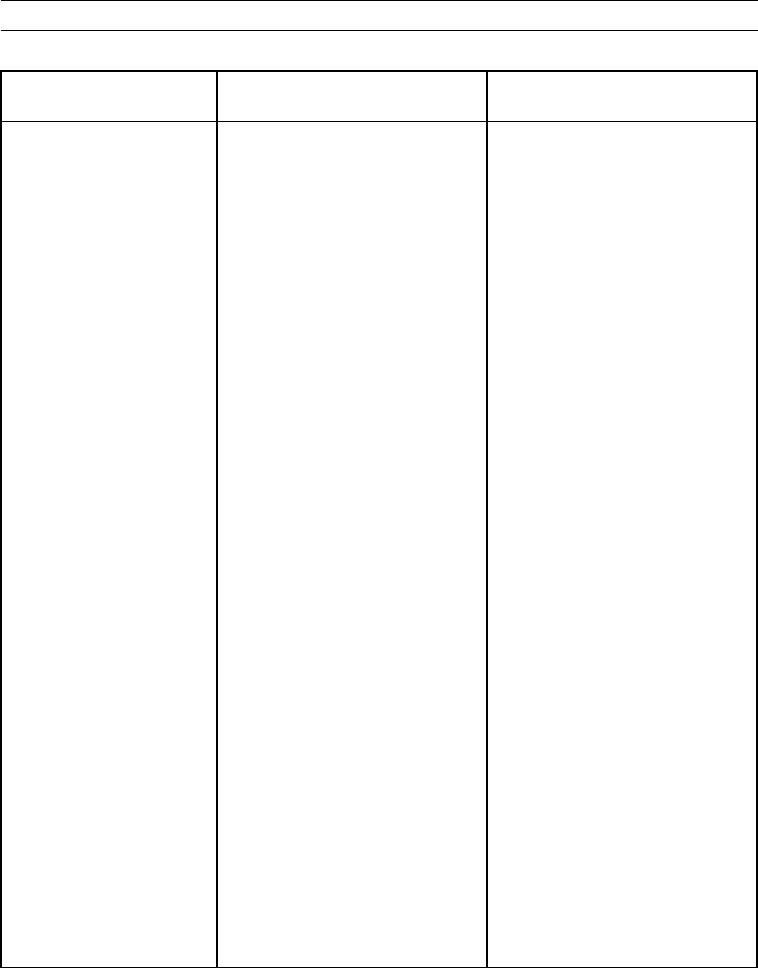

Table 4. Implement Control - Continued.

(MID 082)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Check sensor output.

0352 08 - Continued.

(a) Reconnect wiring harness

connectors to implement ECM.

Reconnect wiring harness

connector to sensor.

(b) At wiring harness connector for

sensor, connect positive lead from

multimeter to contact 5.

(c) At wiring harness connector for

sensor, connect negative lead from

multimeter to contact 2.

(d) Turn battery disconnect and engine

start switches to ON position (TM

5-3805-291-10).

(e) Set multimeter to setting for

1. If PWM signal from sensor is a 500 Hz

frequency (Hz). Measure sensor

signal between 5% and 95%, go to Test 4.

output.

2. If PWM signal from sensor is not a 500

Hz signal or signal is not between 5% and

95%, replace joystick (WP 0219 00).

4. Check if diagnostic code remains active.

(a) Disconnect, inspect, and clean all

wiring harness connectors and

reconnect. Refer to Electrical

Connectors Inspection (WP 0022

00) as necessary.

(b) Reconnect all wiring harness

connectors.

(c) Operate machine (TM 5-3805-291-

10).

1. If CID 0352 FMI 08 is not active, initial

(d) Use messenger to check status of

diagnostic code was probably caused by

CID 0352 FMI 08 (TM 5-3805-

poor electrical connection or short at

291-10).

wiring harness connector that was

disconnected and reconnected. Resume

normal machine operation.

2. If CID 0352 FMI 08 is active, exit this

procedure and repeat this procedure. If

cause of diagnostic code is not found,

replace implement ECM (WP 0060 00).

0009 00-196