TM 5-3805-291-23-1

TROUBLESHOOTING WITH A DIAGNOSTIC CODE - CONTINUED

0009 00

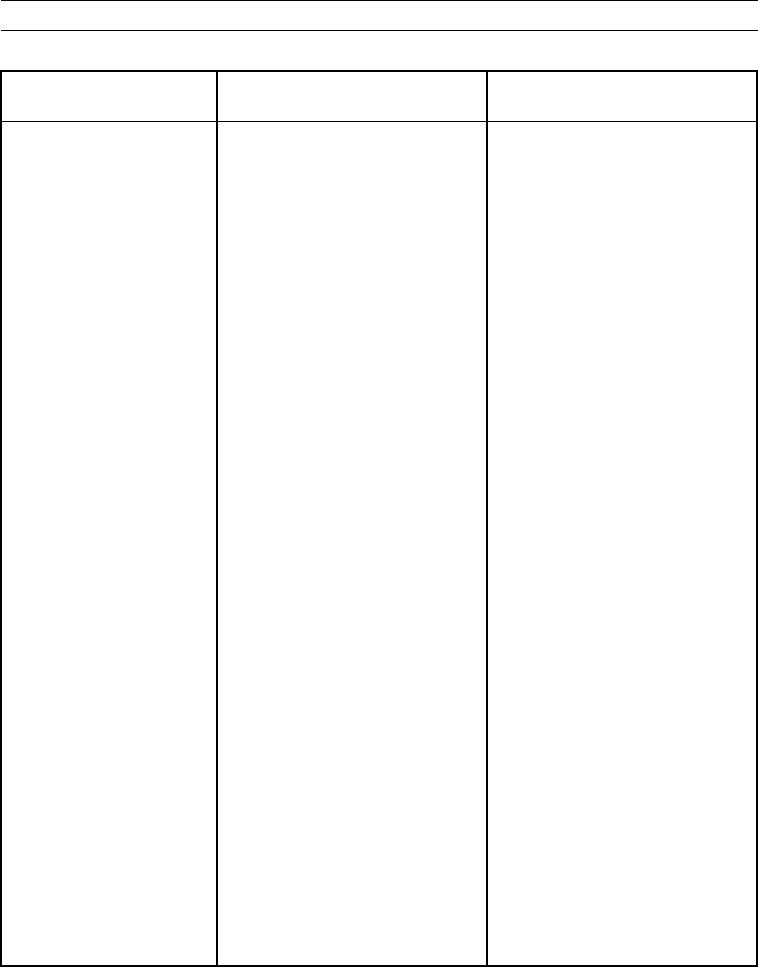

Table 4. Implement Control - Continued.

(MID 082)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

(d) At wiring harness connector for

1. If each resistance measurement is greater

0352 03 - Continued.

implement ECM, measure

than 5,000 Ohms, go to Test 5.

resistance from signal contact J2-

2. If one or more resistance measurements

24 (wire H710-PK) of wiring

is not correct, short is between signal

harness to all possible sources of

contact J2-24 (wire H710-PK) and

+battery circuit. Measure

circuit with low resistance measurement.

resistance to all contacts used in J2

Replace wiring harness in question (WP

and J1 wiring harness connectors.

0195 00 thru WP 0201 00).

5. Check sensor output.

(a) Reconnect wiring harness

connectors to implement ECM.

Reconnect wiring harness

connector to sensor.

(b) At wiring harness connector for

sensor, connect positive lead from

multimeter to contact 5.

(c) At wiring harness connector for

sensor, connect negative lead from

multimeter to contact 2.

(d) Turn battery disconnect and engine

start switches to ON position (TM

5-3805-291-10).

(e) Set multimeter to setting for

1. If PWM signal from sensor is a 500 Hz

frequency (Hz). Measure sensor

signal between 5% and 95%, go to Test 6.

output.

2. If PWM signal from sensor is not a 500

Hz signal or signal is not between 5% and

95%, replace joystick (WP 0219 00).

6. Check if diagnostic code remains active.

(a) Disconnect, inspect, and clean all

wiring harness connectors and

reconnect. Refer to Electrical

Connectors Inspection (WP 0022

00) as necessary.

(b) Reconnect all wiring harness

connectors.

(c) Operate machine (TM 5-3805-291-

10).

0009 00-192