TM 5-3805-291-23-1

TROUBLESHOOTING WITH A DIAGNOSTIC CODE - CONTINUED

0009 00

Table 4. Implement Control - Continued.

(MID 082)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

N OT E

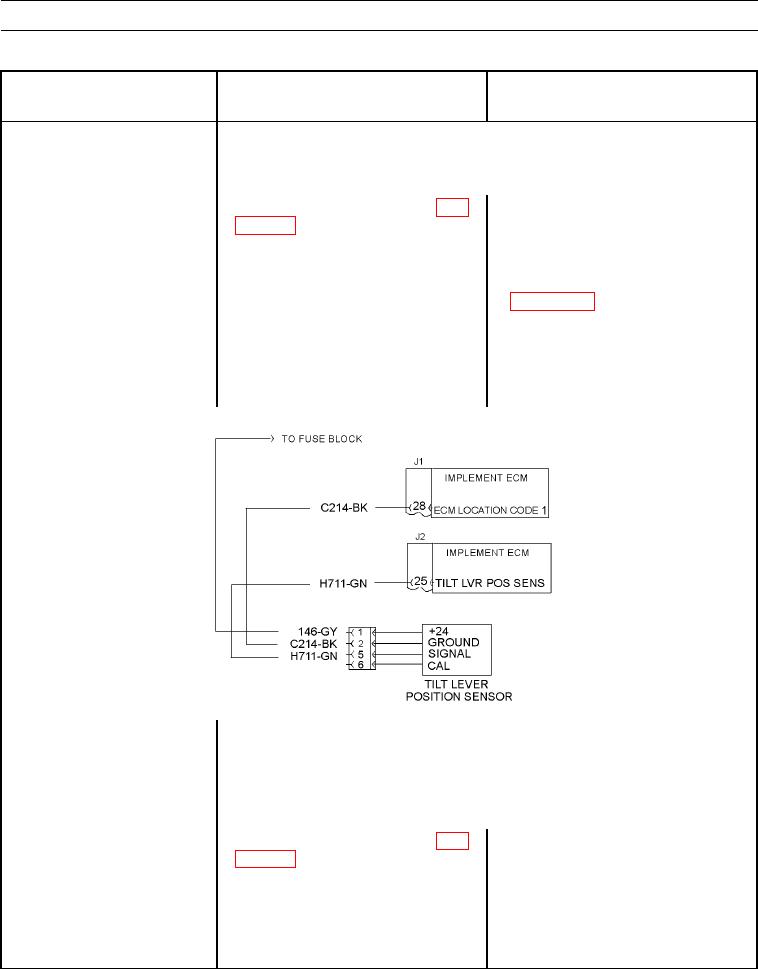

0352 13

Use ET to verify cycle time of each lever position.

Ensure diagnostic code is active.

Recalibrate lever position sensor (WP

1. If calibration causes this diagnostic code

to become inactive, resume normal

machine operation.

2. If calibration has not caused diagnostic

code to become inactive, Connect MSD

(WP 0005 00) and verify cycle time of

each lever position. Refer to Duty Cycle

Signal as a Function of Control Lever

(Table 14) at the end of this work

package, if cycle time values are not

correct, replace joystick (WP 0219 00).

427-C1655

N OT E

0353 00

0353 01

The following procedure may create other diagnostic codes. Ignore these created

diagnostic codes and clear diagnostic codes when original diagnostic code is cor-

rected.

Ensure diagnostic code is active.

Recalibrate lever position sensor (WP

1. If calibration causes this diagnostic code

to become inactive, resume normal

machine operation.

2. If calibration has not caused diagnostic

code to become inactive, replace joystick

(WP 0219 00).