TM 5-3805-291-23-1

TROUBLESHOOTING SYMPTOM INDEX - CONTINUED

0007 00

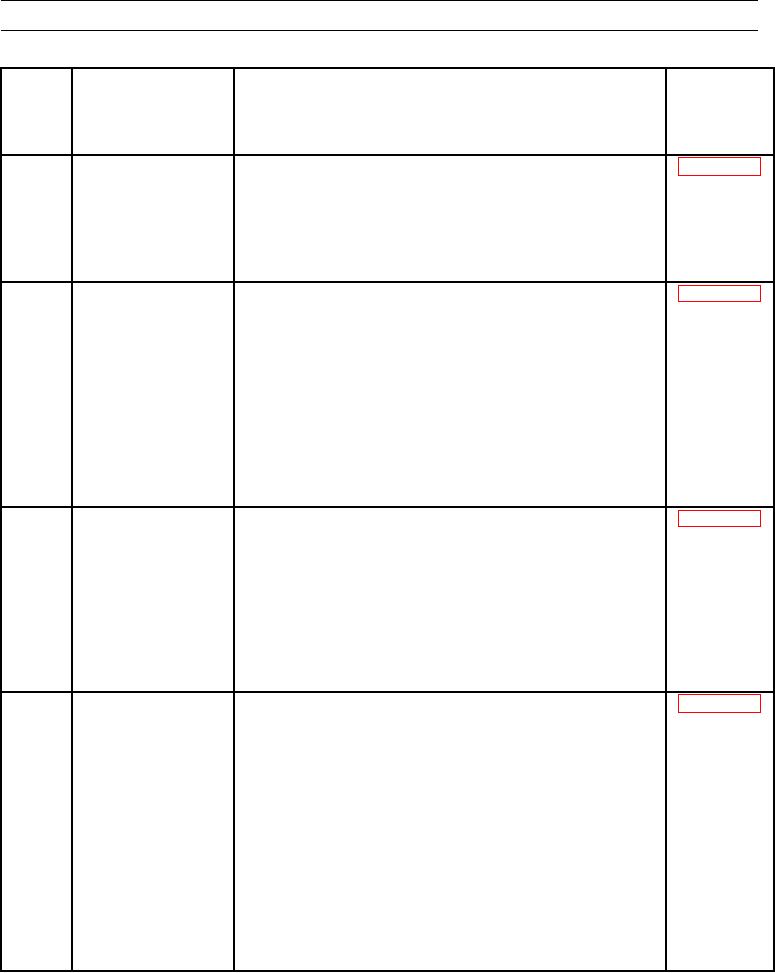

Table 3. MID 082 Implement - Continued.

TROUBLE-

CID

SHOOTING

FMI

FAULT

PROCEDURE

CODE

DESCRIPTION

FAULT CONDITIONS/EFFECTS

PAGE

This failure results in diagnostic codes that are logged against an

0296 02

Cat Data Link

ECM that can not be explained. The Powertrain ECM cannot

Communication with

communicate with the implement ECM or the ECM appears to work

Powertrain Electronic

intermittently.

Control Module Data

Erratic, Intermittent, or

Incorrect

0296 09

Cat Data Link

This diagnostic code is recorded when the powertrain ECM is not

Communication with

sending parameters to the implement ECM at the proper rate and the

Powertrain Electronic

update rate for parameters that are generated by the powertrain ECM is

Control Module

not correct. This code is generated when the data link circuit has an

Abnormal Update

open circuit, the data link circuit is shorted to battery ground, the

powertrain ECM is not operating properly, the software for the

powertrain ECM has been erased, or the powertrain ECM has the wrong

software. When this code is generated, the pilot supply ON/OFF

seem sluggish, the kickouts may stop before the preset location is

reached, or when the engine is being started, the implements will not

be locked out.

This diagnostic code is recorded when the powertrain ECM is not

0296 14

Cat Data Link

sending the necessary parameters to the implement ECM at the proper

Communication with

rate and the update rate for parameters that are generated by the

Powertrain Electronic

powertrain ECM is not correct. The communication failure may be

Control Module

due to disconnected connectors or a faulty wiring harness, the

Parameter Failure

implement or powertrain ECM has the incorrect or incompatible

software installed, or the fuse for the powertrain ECM may have

failed. When this code is generated, some implement functions may

not work properly.

0350 00

Lift Linkage Position

This diagnostic code is recorded when the implement EC determines

Sensor Data Valid but

that the signal for the lift linkage position sensor is too high. The

Above Normal

implement ECM has read a sensor value that is greater than the

Operating Range

calibrated upper range of the sensor. The lift linkage position sensor is

a PWM sensor. The signal wire for the lift linkage position sensor

connected to connector contact J2-32 (wire C530 BU) of the implement

ECM. Possible cause are the rotation or replacement of the lift linkage

position sensor without proper recalibration may cause a diagnostic

code or position sensor could rotate farther than normal in one direction.

When this code is generated, the lift cylinder snubbing, lift kickouts,

and the lower kickouts may not work correctly and if the diagnostic

code is active for three seconds, then the 350-13 diagnostic code will

become active.

0007 00-28