TM 5-3805-291-23-1

TROUBLESHOOTING SYMPTOM INDEX - CONTINUED

0007 00

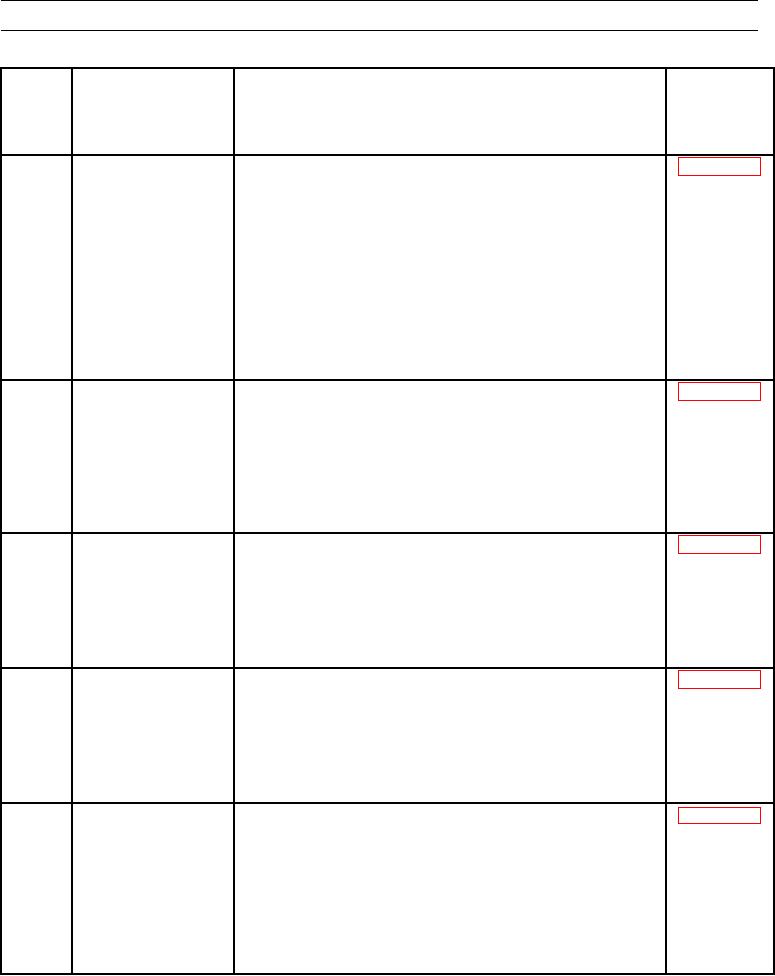

Table 3. MID 082 Implement - Continued.

TROUBLE-

CID

SHOOTING

FMI

FAULT

PROCEDURE

CODE

DESCRIPTION

FAULT CONDITIONS/EFFECTS

PAGE

0351 08

Tilt Linkage Position

This diagnostic code is recorded when the implement ECM determines

Sensor Abnormal

that the signal for the tilt linkage position sensor has an abnormal pulse

Frequency, Pulse, or

width, abnormal frequency, or an abnormal period. The tilt linkage

Period

position sensor is a PWM sensor. The signal wire for the tilt linkage

position sensor connects to connector contact J2-33 (wire H718 GY) of

the implement ECM. The possible causes for this diagnostic code are

the circuit for the +battery to the sensor has a intermittent connection,

the return circuit from the sensor has a intermittent connection, the

signal circuit from the sensor has a intermittent connection, or the sensor

has failed. When this code is generated, tilt kickouts, dump rate control,

FRAC, and dump stop snubbing will not operate. The active fault must

be removed before the implement features will work properly.

0351 13

Tilt Linkage Position

This diagnostic code is recorded when the implement ECM determines

Sensor Out of

that the tilt linkage position sensor is out of calibration. The tilt linkage

Calibration

position sensor is a PWM sensor. The possible causes for this diagnostic

code are the sensor harness was disconnected for more than 5 seconds

while the system was powered or the signal for the rotary position

sensor was lost for more than 5 seconds. When this code is generated,

tilt kickouts, dump rate control, FRAC, and dump stop snubbing will

not operate and the valve calibration will not work.

0352 00

Lift Lever Position

This diagnostic code is recorded when the implement ECM determines

Sensor Data Valid but

that the signal from the lift lever position sensor is too high. The lift

Above Normal

lever position sensor is a 500 Hz PWM sensor. One possible cause is

Operating Range

the lift lever position sensor needs recalibrated. When this code is

generated, if 0352 00 is active for at least three seconds, the 352-13

diagnostic code will be active and the 352-00 diagnostic code will

become inactive.

0352 01

Lift Lever Position

This diagnostic code is recorded when the implement ECM determines

Sensor Data Valid but

that the signal for the lift lever position sensor is too low. The lift lever

Below Normal Operating

position sensor is a pulse width modulated sensor. One possible cause

Range

is the lift lever position sensor needs recalibrated. When this code is

generated, if 0352 01 is active for at least three seconds, then the 35213

diagnostic code will become active and the 352-01 diagnostic code will

become inactive.

0352 03

Lift Lever Position

This diagnostic code is recorded when the ECM determines that the

Sensor Voltage Above

voltage for the lift lever position sensor is too high. The signal wire

Normal or Shorted High

connects to connector contact J2-24 (wire H710 PK) of the implement

ECM. The lift lever position sensor is a 500 Hz PWM sensor. The

possible causes for this diagnostic code are the signal circuit is shorted

to the +battery, the signal circuit is open, the ground circuit is open, or

the sensor has failed. When this code is generated, the lift function will

be disabled until the diagnostic code is cleared. Also, the lift lever must

be recentered.

0007 00-32