TM 5-3805-291-23-1

TROUBLESHOOTING WITH A DIAGNOSTIC CODE - CONTINUED

0009 00

Table 4. Implement Control - Continued.

(MID 082)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

427-C1666

N OT E

0491 06

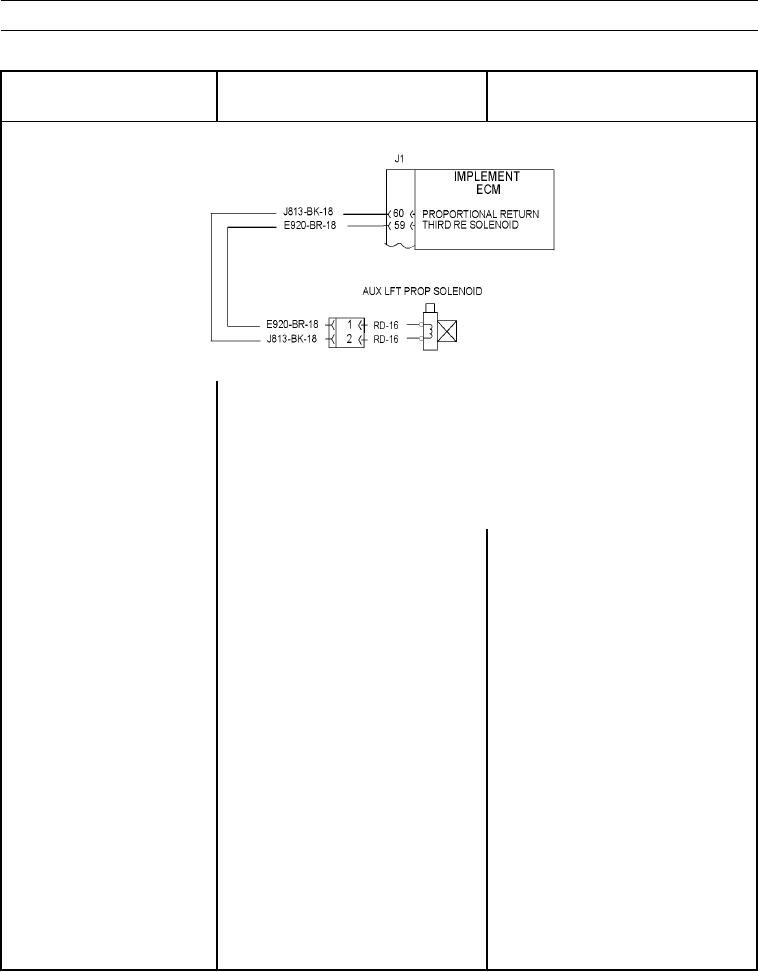

All solenoid return lines connect to contact J1-60 (wire J813-BK) of implement

ECM.

The following test procedure may create other diagnostic codes. Ignore these

created diagnostic codes and clear diagnostic codes when original diagnostic

code is corrected.

Ensure diagnostic code indicator is active and diagnostic code is active.

1. Check solenoid.

(a) Turn battery disconnect and engine

start switches to ON position (TM

5-3805-291-10).

(b) Observe ON/OFF status of

diagnostic code indicator.

(c) Disconnect auxiliary rearward

1. If diagnostic code indicator remains

proportioning solenoid from wiring

active, harness or implement ECM has

harness (WP 0218 00).

failed. Go to Test 2.

2. If diagnostic code indicator is inactive,

solenoid or connecting harness has

failed. Repeat this test to verify failure.

Replace solenoid (WP 0218 00). Replace

wiring harness in question (WP 0195 00

thru WP 0201 00).

2. Check for shorted wiring harness.

(a) Turn battery disconnect switch to

OFF position (TM 5-3805-291-10).

(b) Solenoid valve remains

disconnected.