TM 5-3805-298-23-2

0155

Table 1. Kickout System Will Not Operate or Operates Improperly Continued.

0155

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Resistance 5.0 Ohms or Less - Install

6. Using digital multimeter

Kickout System Will Not

kickout fuse (TM 5-3805-298-10).

(WP 0174), measure resistance

Operate or Operates

between kickout fuse terminals.

Improperly - Continued

Proceed to Test Step 36.

Resistance Greater Than 5.0 Ohms -

Replace bucket kickout position sensor

(WP 0297).

Replace kickout fuse (TM 5-3805-298-

10).

Proceed to Test Step 60.

Test Step 36. Test for Shorted Fork

Kickout Position Sensor.

1. Connect connector N-C3 to fork

kickout position sensor (WP 0012,

Figure 234).

2. Turn battery disconnect switch and

ignition switch to ON position

(TM 5-3805-298-10).

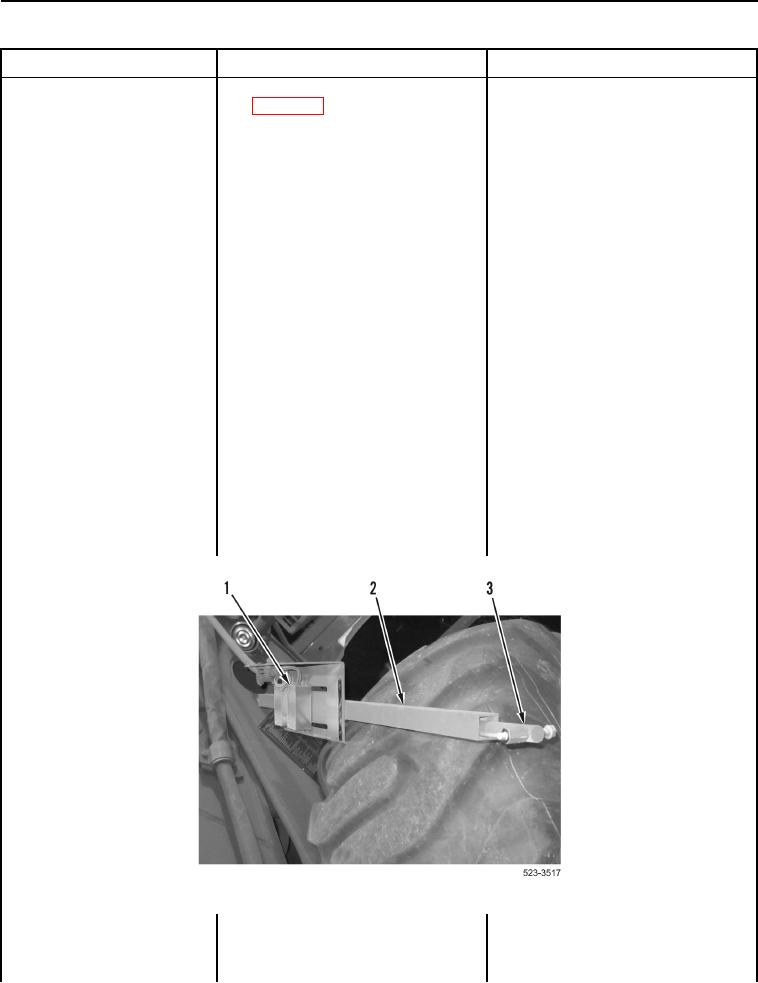

3. Slide shaft (Figure 25, Item 3) into

channel (Figure 25, Item 2) so that

shaft magnet passes over fork

kickout position sensor (Figure 25,

Item 1). Slide shaft out of channel

so that shaft magnet passes over

fork kickout position sensor.

Figure 25. Fork Kickout Position Sensor.

0155