TM 5-3805-298-23-2

0155

Table 1. Kickout System Will Not Operate or Operates Improperly Continued.

0155

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

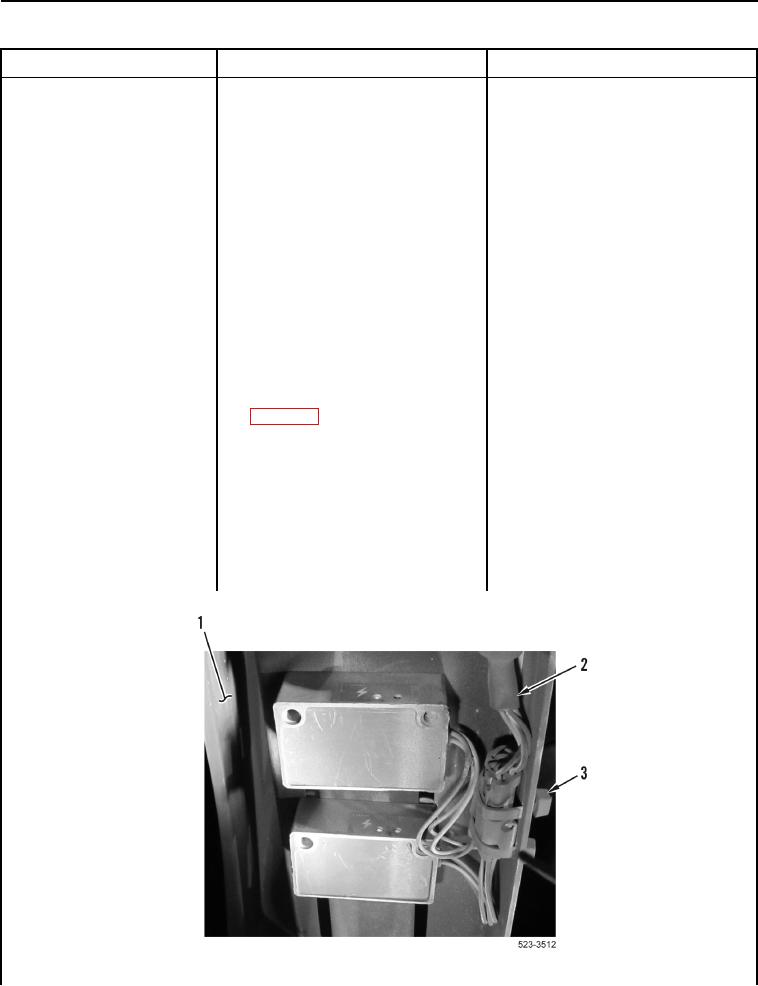

2. Remove two tiedown straps

Kickout System Will Not

(Figure 26, Item 3) from mounting

Operate or Operates

bracket (Figure 26, Item 1) and

Improperly - Continued

wiring harness (Figure 26, Item 2).

Discard tiedown straps.

3. Disconnect connector N-C2 from

bucket kickout position sensor

(WP 0012, Figure 233).

4. Turn battery disconnect switch and

ignition switch to ON position

(TM 5-3805-298-10).

5. Set implement disable switch to

unlock position

(TM 5-3805-298-10).

6. Set kickout switch to ON position

(TM 5-3805-298-10).

7. Using digital multimeter

Voltage 0.5 V or Greater Proceed to

(WP 0174), test for voltage

Test Step 40.

between connector N-C2

Voltage Less Than 0.5 V and Directed

terminal B (WP 0012, Figure 233)

Here From Test Step 8 Replace

and ground.

bucket kickout position sensor

(WP 0297).

Proceed to Test Step 60.

Voltage Less Than 0.5 V and Directed

Here From Test Step 11 Proceed to

Test Step 53.

Figure 26. Tiedown Straps.

0155