TM 5-3805-291-23-1

TROUBLESHOOTING WITH A DIAGNOSTIC CODE - CONTINUED

0009 00

Table 4. Implement Control - Continued.

(MID 082)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

(d) Observe ON/OFF status of

1. If diagnostic code indicator is inactive,

0354 13 - Continued.

diagnostic code indicator as lift arm

calibration corrected diagnostic code.

is fully raised and lowered.

Clear diagnostic code.

2. If diagnostic code indicator is active,

perform calibration for main control

valve again. Also, ensure diagnostic code

indicator is active for this diagnostic

code. If cause is not found, replace

solenoid and repeat calibration. If this

does not eliminate diagnostic code,

replace implement ECM (WP 0060 00).

427-C1657

N OT E

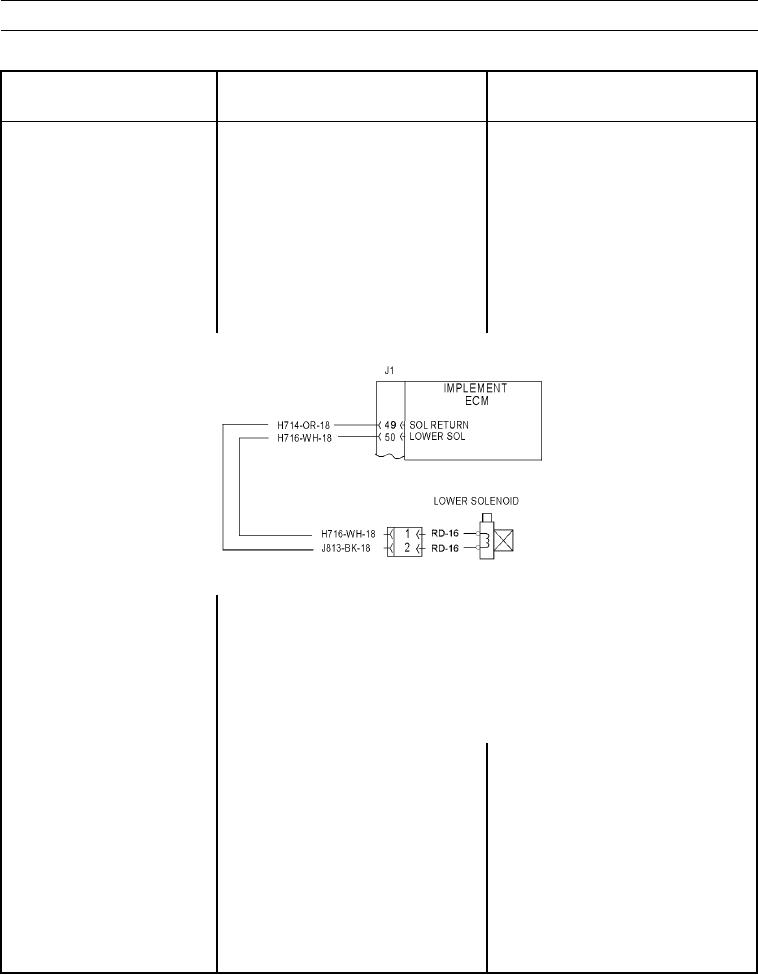

0355 03

All solenoid return lines connect to contacts J1-49 (wire H714-OR and J1-50

wire H716-WH) of implement ECM.

The following procedure may create other diagnostic codes. Ignore these created

diagnostic codes and clear diagnostic codes when original diagnostic code is cor-

rected.

Ensure diagnostic code is active and that diagnostic code indicator is active.

1. Check solenoid.

(a) Turn engine start switch to OFF

position (TM 5-3805-291-10).

(b) Disconnect lower solenoid from

wiring harness (WP 0218 00).

(c) Turn engine start switch to ON

position (TM 5-3805-291-10).

(d) Place direction lever in NEUTRAL

position (TM 5-3805-291-10).