TM 5-3805-291-23-1

TROUBLESHOOTING WITH A DIAGNOSTIC CODE - CONTINUED

0009 00

Table 4. Implement Control - Continued.

(MID 082)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

427-C1657

N OT E

0355 05

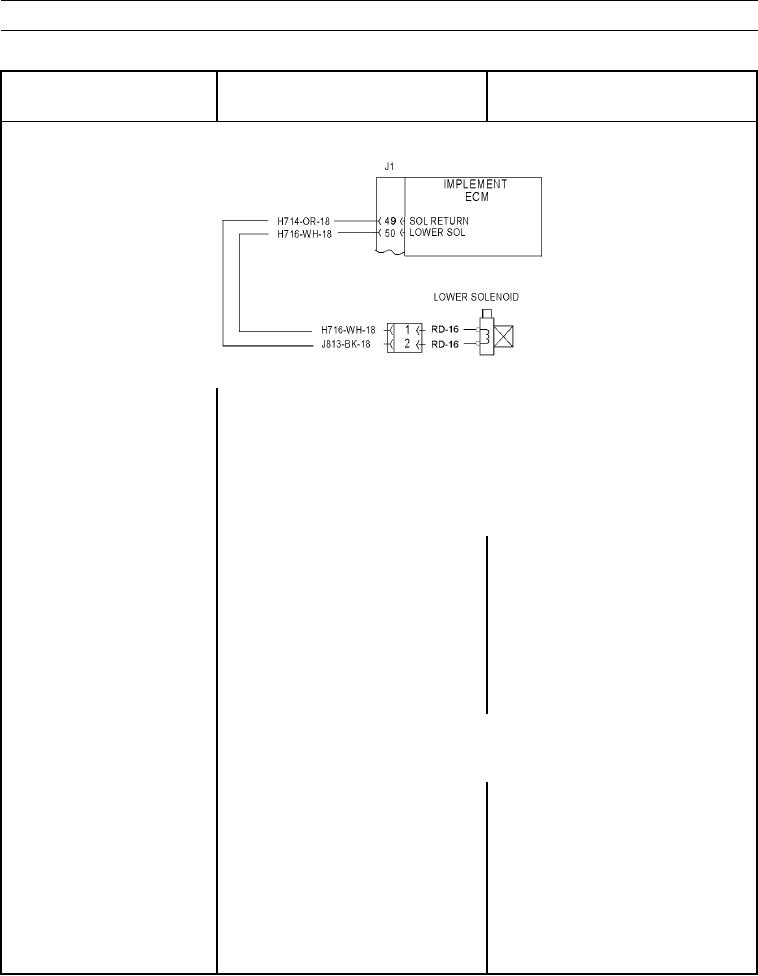

All solenoid return lines for solenoid are joined and return lines are connected to

contact J1-50 (wire H716-WH) of implement ECM.

The following procedure may create other diagnostic codes. Ignore these created

diagnostic codes and clear diagnostic codes when original diagnostic code is cor-

rected.

Ensure diagnostic code is active and diagnostic code indicator is active.

1. Check solenoid.

(a) Turn battery disconnect and engine

start switches to ON position (TM

5-3805-291-10).

(b) Disconnect lower solenoid from

wiring harness (WP 0218 00).

(c) Observe ON/OFF status of

diagnostic code indicator.

N OT E

Approximate resistance of a proportional solenoid valve is from 6 to

12 Ohms.

(d) At wiring harness connector for

1. If diagnostic code indicator remains

solenoid, place a jumper wire

active, go to Test 2.

between contact 1 (wire H714-OR) 2. If diagnostic code indicator is inactive,

and contact 2 (wire H716-WH).

repeat this test to verify failure. Replace

solenoid (WP 0218 00) or wiring harness

in question (WP 0195 00 thru WP 0201

00).