18

TM 5-3805-292-23

FIELD MAINTENANCE

-

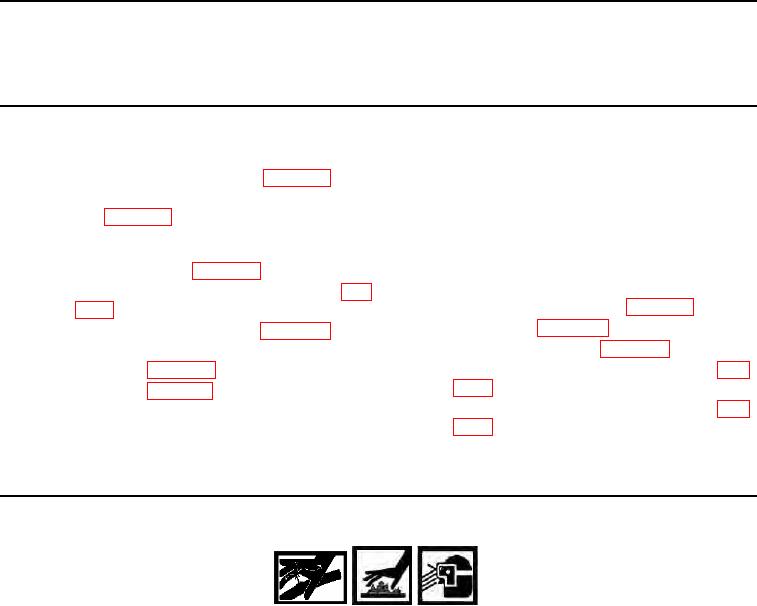

MAIN HYDRAULIC VALVE MAINTENANCE

0

089

REMOVAL, DISASSEMBLY, CLEANING AND INSPECTION, ASSEMBLY, INSTALLATION

INITIAL SETUP

Personnel Required

Tools and Special Tools

0

0

Tool Kit, General Mechanic's (WP 0178, Item

Two

0

33)

0

References

0

SATS (WP 0178, Item 30)

0

TM 5-3805-292-10

0

Materials/Parts

TM 5-3805-292-23P, Figure 55

0

0

Cap Set, Protective (WP 0179, Item 2)

0

Equipment Conditions

0

Cleaning Compound, Solvent, Type III (WP

Hydraulic reservoir drained (WP 0009)

0179, Item 3)

0

0

Seat removed (WP 0126)

Oil, Lubricating, OE/HDO-10 (WP 0179, Item

0

Joystick valve removed (WP 0084)

16)

0

0

Rag, Wiping (WP 0179, Item 19)

LH joystick console bracket removed (WP

0

Tag, Marker (WP 0179, Item 30)

0

0

RH joystick console bracket removed (WP

Kit, Seal

0

O-ring

0

0

Locknut

Estimated Time to Complete

0

0

4.0 Hr

0

0

WARN I N G

When servicing this machne, performing maintenance, or disposing of hazardous

i

materials, consult your unit/local hazardous waste disposal center or safety office for local

regulatory guidance. If further information is needed, please contact The Army

Environmental Hotline at 1-800-872-3845.

DO NOT disconnect or remove any hydraulic system lines or fitting unless engine is shut

down and hydraulic system pressure has been relieved. Tighten all connections before

applying pressure. Escaping hydraulic fluid under pressure can penetrate the skin.

At operating temperature, hydraulic oil is hot.Allow hydraulic oil to cool before removing

any hydraulic fitting.

To prevent injury to personnel, wear protective eye covering and gloves.

Failure to follow these warnings may result in injury or death to personnel.

C AU T I O N

Cap all hydraulic hose and line ends along with component connections during removal to

protect against contamination. Failure to follow this caution may result in damage to

equipment.

0089-1